Why Is My Low-Temperature Valve Not Working? Troubleshooting Tips

Picture this scenario: You're overseeing a critical industrial process requiring precise temperature control at -60°C, and suddenly your Low-Temperature Control Valve begins malfunctioning. Production halts, costs escalate, and safety concerns mount. This frustrating situation affects countless operators in petrochemical plants, LNG facilities, and cryogenic applications worldwide. Understanding why your low-temperature valve fails and knowing how to troubleshoot it effectively can save thousands in downtime costs while maintaining operational safety. This comprehensive guide provides expert troubleshooting strategies to diagnose and resolve common Low-Temperature Control Valve issues quickly and efficiently.

Common Causes of Low-Temperature Control Valve Failures

-

Thermal Expansion and Contraction Issues

Low-temperature applications present unique challenges that standard valves cannot handle effectively. When a Low-Temperature Control Valve operates in extreme cold conditions ranging from -60°C to -196°C, thermal expansion and contraction create significant stress on valve components. The valve body, trim, and sealing elements experience different rates of expansion, leading to misalignment, binding, or seal failure. Materials that work perfectly at ambient temperatures may become brittle or lose their elastic properties in cryogenic conditions. CEPAI's Low-Temperature Control Valves feature specially designed extended bonnets and cryogenic-grade materials like 316L stainless steel that maintain integrity even at -196°C. The pressure balance spool design compensates for thermal stress while providing reliable flow control performance throughout the operating temperature range.

-

Seal and Packing Degradation

Traditional valve seals and packing materials fail rapidly in low-temperature environments, causing internal and external leakage. Standard rubber seals become rigid and crack when exposed to extreme cold, while conventional PTFE packing loses its sealing properties. The thermostatic element might have stopped working or might have a problematic O-ring, which is particularly critical in low-temperature applications where seal integrity is paramount. CEPAI's Low-Temperature Control Valves utilize flexible graphite and specialized PTFE packing systems designed for cryogenic service. These materials maintain their sealing properties across the entire operating temperature range, ensuring leak-tight performance and meeting strict environmental and safety requirements.

Diagnostic Procedures for Low-Temperature Control Valves

-

Electrical System Troubleshooting

Electric actuator problems frequently cause Low-Temperature Control Valve malfunctions, especially when exposed to extreme temperature variations. The electrical components must withstand ambient temperatures from -30°C to +70°C while maintaining precise control signal accuracy. Common electrical issues include control signal drift, actuator positioning errors, and power supply fluctuations. CEPAI's electric actuators operate on standard 220V or 380V power supplies with 4-20mA control signals, providing reliable performance in harsh environments. When troubleshooting electrical problems, verify proper voltage supply, check control signal integrity using calibrated instruments, and confirm actuator positioning feedback matches the control system demands. The electric actuator's ability to provide remote control capability reduces manual intervention requirements while improving operational safety in hazardous low-temperature environments.

-

Process Conditions Analysis

Debris from the water lines can get into a valve cartridge and cause temperature fluctuations, and this contamination issue becomes more severe in low-temperature applications where solidification can occur. Process fluid contamination, pressure variations, and flow rate changes significantly impact Low-Temperature Control Valve performance. Particulate matter can freeze within valve trim, creating flow restrictions or preventing proper valve closure. Pressure fluctuations affect the pressure balance spool's ability to maintain stable control characteristics. CEPAI's Low-Temperature Control Valves feature straight cage-type ball valve designs with equal percentage or linear flow characteristics, providing superior performance across varying process conditions. The nominal diameter range from DN15 to DN400mm accommodates diverse application requirements while maintaining precise flow control accuracy.

Maintenance Best Practices for Low-Temperature Control Valves

-

Preventive Maintenance Strategies

Implementing comprehensive preventive maintenance programs significantly reduces Low-Temperature Control Valve failure rates and extends service life. Regular inspection schedules should focus on actuator calibration, seal condition assessment, and control signal verification. Temperature cycling tests help identify potential material degradation before failure occurs. CEPAI's intelligent manufacturing approach incorporates predictive maintenance capabilities through IoT connectivity and remote monitoring systems. These advanced features enable real-time valve performance tracking, early fault detection, and optimized maintenance scheduling. The company's AR remote operation and maintenance guidance system provides immediate technical support, reducing downtime and improving maintenance efficiency.

-

Component Replacement Guidelines

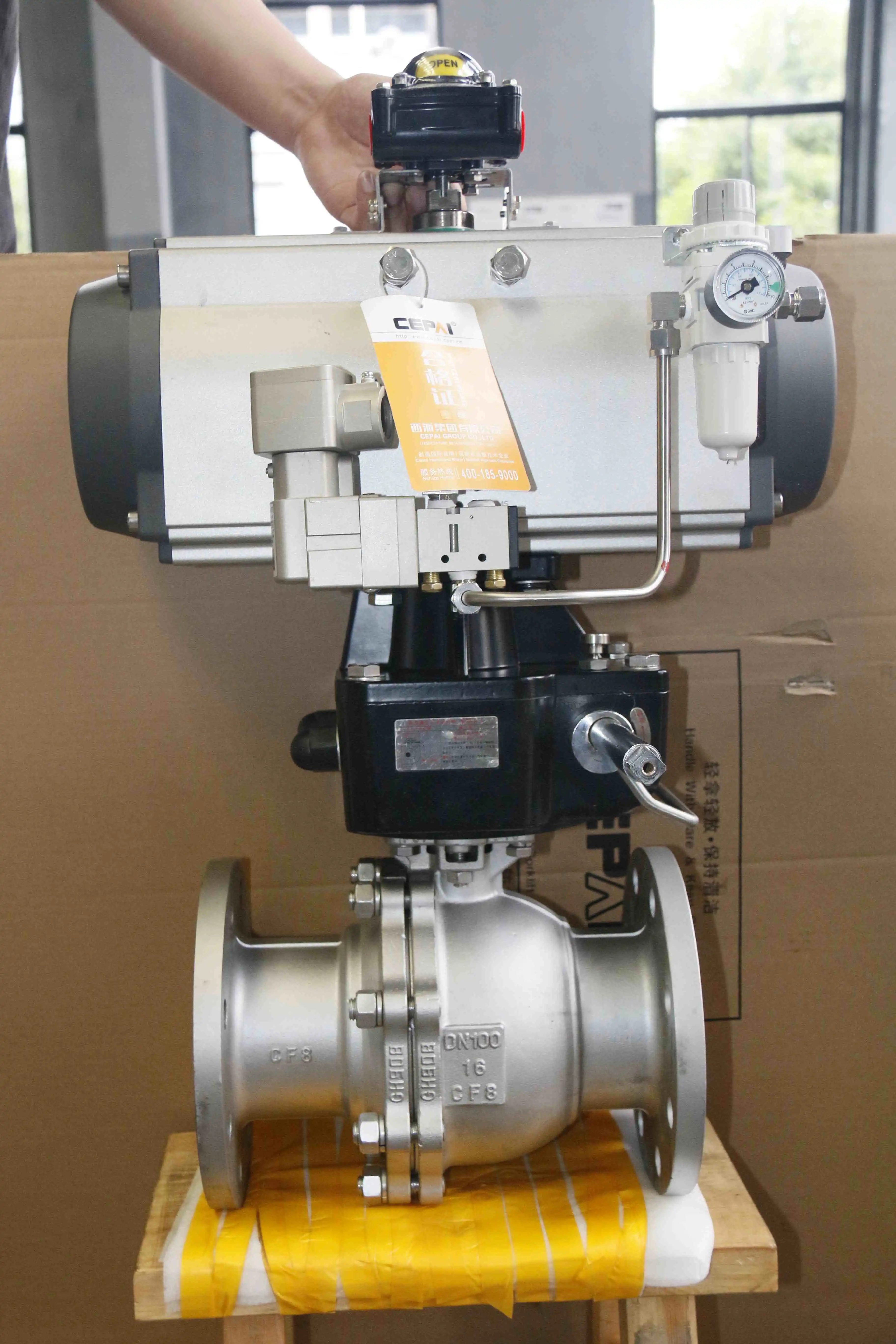

When Low-Temperature Control Valve components require replacement, using proper materials and procedures is essential for reliable operation. The valve body materials including WCB, CF8, and CF8M provide excellent corrosion resistance and low-temperature toughness. Internal components utilizing 304, 316, and 316L stainless steel grades maintain mechanical properties at cryogenic temperatures. CEPAI's modular design philosophy enables efficient component replacement without complete valve removal from the process line. The bolt-pressed gland design facilitates packing replacement, while the pressure balance spool can be serviced through standard maintenance procedures. Quality control measures ensure all replacement parts meet API 6A, API 6D, and relevant international standards for low-temperature service applications.

Advanced Troubleshooting Techniques

-

Flow Characteristic Optimization

Low-Temperature Control Valve performance depends heavily on proper flow characteristic selection and trim design optimization. Equal percentage characteristics provide better control stability at low flow rates, while linear characteristics offer improved controllability across the full operating range. CEPAI's Low-Temperature Control Valves feature both characteristics options, allowing process engineers to select optimal performance for specific applications. The straight cage-type design minimizes pressure drop while maximizing rangeability, essential for precise temperature control in cryogenic processes. Understanding process dynamics and selecting appropriate valve sizing ensures optimal performance throughout the operating envelope.

-

System Integration Considerations

Modern Low-Temperature Control Valve installations require seamless integration with distributed control systems, safety instrumented systems, and process optimization platforms. CEPAI's valves support standard 4-20mA control signals with optional feedback capabilities, enabling bidirectional communication with control systems. The company's digital transformation initiatives include IoT connectivity, cloud-based monitoring, and artificial intelligence-driven optimization algorithms. These advanced features provide operators with comprehensive system visibility, enabling proactive troubleshooting and performance optimization. Integration with enterprise resource planning systems facilitates inventory management, maintenance scheduling, and performance tracking across multiple facilities.

Safety Considerations and Standards Compliance

-

Regulatory Compliance Requirements

Low-Temperature Control Valve installations must comply with stringent safety and performance standards including API, ASME, and international regulations. CEPAI maintains comprehensive certifications including API Q1, API 6A, API 6D, ISO 9001, ISO 14001, and ISO 45001, ensuring products meet global requirements. The company's CNAS nationally recognized laboratory conducts thorough testing to verify performance characteristics and safety compliance. SIL (Safety Integrity Level) certifications for butterfly valves, ball valves, and control valves demonstrate the commitment to functional safety in critical applications. Safety protocols for Low-Temperature Control Valve maintenance include proper personal protective equipment, lockout/tagout procedures, and emergency response planning. The extreme temperature conditions require specialized training for maintenance personnel and appropriate tools designed for cryogenic service. CEPAI's comprehensive training programs ensure operators understand proper installation, operation, and maintenance procedures while maintaining safety standards throughout the valve lifecycle.

Conclusion

Effective troubleshooting of Low-Temperature Control Valve issues requires systematic analysis of thermal, mechanical, electrical, and process-related factors. By understanding common failure modes, implementing proper diagnostic procedures, and following maintenance best practices, operators can significantly improve valve reliability and performance. CEPAI's advanced Low-Temperature Control Valve technology, combined with comprehensive support services, provides the foundation for successful cryogenic process operations.

Cooperate with CEPAI Group Co., LTD.

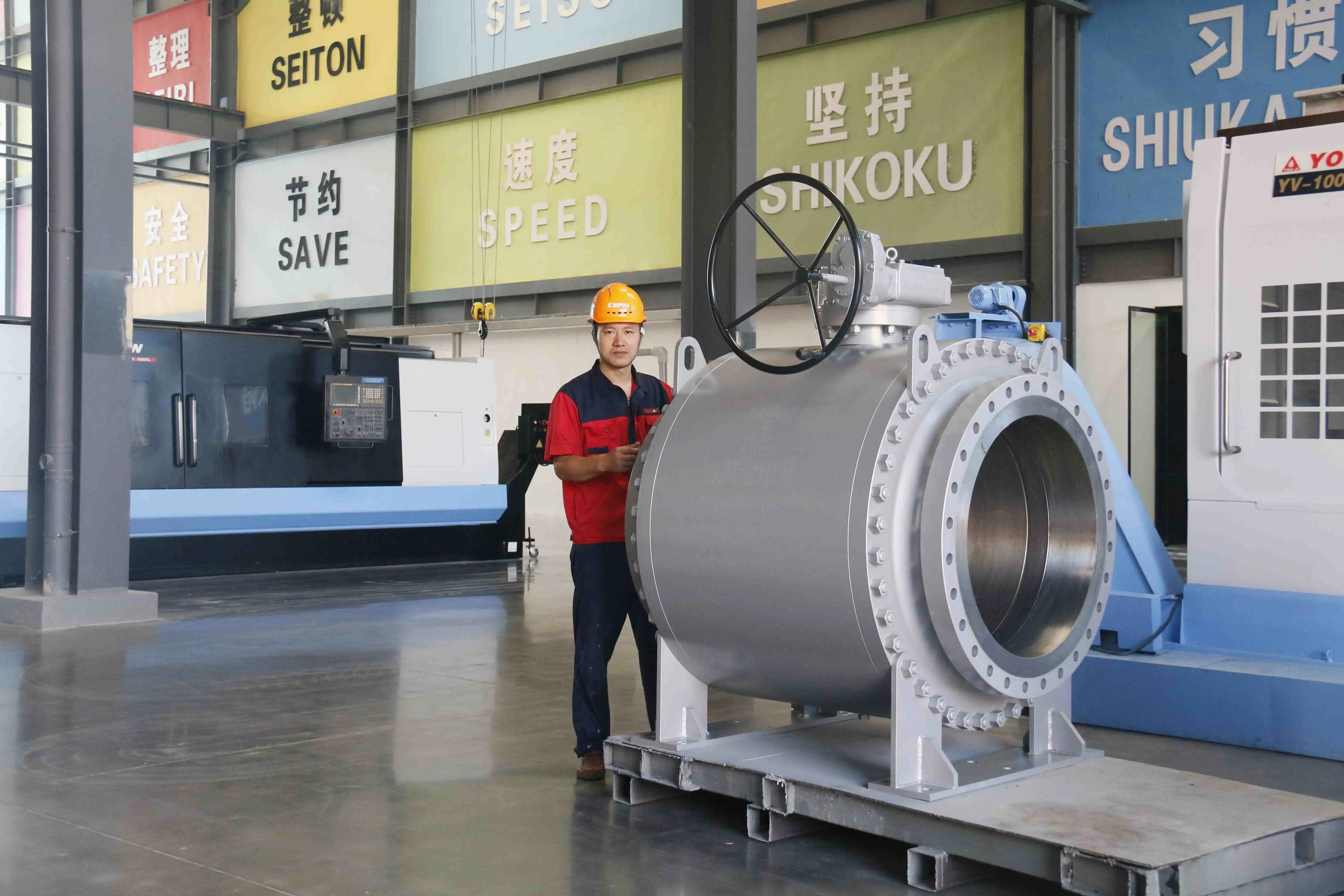

CEPAI Group Co., LTD. stands as China's premier Low-Temperature Control Valve manufacturer, offering unmatched expertise in cryogenic valve technology since 2009. As a national high-tech enterprise with 200 million yuan registered capital, CEPAI operates state-of-the-art manufacturing facilities spanning 56,000 square meters in Jiangsu Province. Our China Low-Temperature Control Valve factory features the Asia Pacific region's longest high-precision intelligent manufacturing production line, ensuring superior quality and reliability. As a trusted China Low-Temperature Control Valve supplier to PetroChina, Sinopec, and CNOOC, we deliver exceptional value through innovative design and rigorous quality control.

Our comprehensive product portfolio includes High Quality Low-Temperature Control Valve solutions for diverse industrial applications at competitive Low-Temperature Control Valve prices. From standard DN15-400mm configurations to custom-engineered solutions, CEPAI serves as your reliable China Low-Temperature Control Valve wholesale partner. With our Low-Temperature Control Valve for sale backed by extensive certifications and proven performance, we invite you to experience the CEPAI difference. Contact our technical experts at cepai@cepai.com for personalized consultation and competitive quotes that address your specific application requirements.

FAQ

Q: What temperature range can CEPAI's Low-Temperature Control Valves handle?

A: CEPAI's Low-Temperature Control Valves operate effectively from -196°C to -20°C, with extended bonnet designs for extreme cryogenic applications.

Q: How do I determine the correct valve size for my low-temperature application?

A: Valve sizing depends on flow rate, pressure drop, and fluid properties. Our technical team provides comprehensive sizing calculations and recommendations.

Q: What makes CEPAI's valves different from standard control valves?

A: CEPAI's valves feature specialized materials, extended bonnets, pressure balance spools, and cryogenic-grade sealing systems designed specifically for low-temperature service.

Q: How often should Low-Temperature Control Valves be calibrated?

A: Calibration frequency depends on application criticality and operating conditions. Typically, quarterly calibration ensures optimal performance and safety compliance.

References

1. "Industrial Valve Technology and Applications in Cryogenic Systems" - Smith, J.A. and Johnson, M.B., Industrial Press.

2. "Low Temperature Materials and Engineering" - Peterson, R.L., McGraw-Hill Professional.

3. "Process Control Instrumentation Technology" - Curtis D. Johnson, Prentice Hall.

4. "Valve Selection and Specification Guide" - American Society of Mechanical Engineers (ASME).

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI