What Is a Bellows Seal Electric Control Valve and How Does It Work?

A bellows seal electric control valve represents a revolutionary advancement in industrial fluid control technology, combining the leak-proof capabilities of bellows sealing with the precision of electric actuation. This sophisticated valve design utilizes a flexible metal bellows to create a hermetic seal between the valve stem and body, while incorporating electric actuators for automated flow control. The Electric Control Valve technology has transformed how industries manage critical processes where leakage is absolutely unacceptable, such as chemical processing, pharmaceutical manufacturing, and high-pressure applications. Unlike traditional valves that rely on packing glands, these valves eliminate the risk of fugitive emissions through their innovative bellows design, making them indispensable for modern industrial operations requiring zero-leakage performance and precise flow regulation.

Advanced Design Features and Technical Advantages

Superior Sealing Technology and Materials

The bellows seal electric control valve incorporates cutting-edge sealing technology that fundamentally differs from conventional valve designs. The metallic bellows, typically manufactured from stainless steel alloys such as Inconel, Hastelloy, or specialized duplex steels, provides exceptional durability and corrosion resistance. This Electric Control Valve design eliminates the need for traditional packing materials, which are prone to wear, deterioration, and eventual leakage. The bellows acts as a flexible barrier that accommodates stem movement while maintaining absolute seal integrity throughout the valve's operational life. Advanced manufacturing techniques ensure that each bellows undergoes rigorous testing, including pressure cycling, fatigue testing, and helium leak detection to guarantee zero-emission performance. The electric actuator integration allows for precise positioning control, typically offering accuracy within ±1% of the full stroke range, making these valves ideal for applications requiring exact flow modulation and tight shut-off capabilities.

Intelligent Control Systems and Automation Integration

Modern bellows seal electric control valves feature sophisticated control systems that integrate seamlessly with industrial automation networks. These Electric Control Valve systems incorporate advanced position feedback mechanisms, including potentiometric, magnetic, or optical encoders that provide real-time stem position data. The electric actuators utilize servo motor technology or stepper motors, delivering precise torque control and consistent performance across varying load conditions. Smart valve positioners equipped with digital communication protocols such as HART, Foundation Fieldbus, or Profibus enable remote monitoring, diagnostics, and calibration. The integration of artificial intelligence algorithms allows for predictive maintenance scheduling, performance optimization, and automatic compensation for process variables. These intelligent features significantly reduce operational costs while enhancing system reliability and safety margins in critical industrial applications.

Enhanced Durability and Performance Characteristics

The construction of bellows seal electric control valves emphasizes long-term reliability and performance consistency under demanding operating conditions. The valve body typically features forged or cast construction using materials such as carbon steel, stainless steel, or exotic alloys depending on application requirements. The Electric Control Valve design incorporates reinforced stem guides, precision-machined seating surfaces, and anti-cavitation trims to handle high-pressure drops and erosive media. The bellows assembly undergoes specialized heat treatment processes to optimize fatigue resistance and extend operational life beyond 100,000 cycles. Advanced surface treatments, including hard-facing, coating applications, and specialized polishing techniques, enhance wear resistance and maintain sealing performance throughout the valve's service life. These engineering improvements result in significantly reduced maintenance requirements and extended operational intervals compared to conventional control valve technologies.

Industrial Applications and Market Segments

Chemical Processing and Petrochemical Industries

Bellows seal electric control valves play a critical role in chemical processing operations where handling toxic, corrosive, or volatile substances demands absolute leak prevention. The petrochemical industry relies heavily on these Electric Control Valve systems for applications including reactor control, distillation column management, and pipeline regulation. The zero-emission design meets stringent environmental regulations while protecting personnel from exposure to hazardous chemicals. These valves excel in high-temperature applications up to 650°C and high-pressure systems exceeding 400 bar, making them suitable for steam cracking units, reforming processes, and polymerization reactions. The electric actuation provides rapid response times essential for emergency shutdown systems and process safety interlocks. Major petrochemical complexes worldwide have adopted these valve technologies to achieve compliance with emissions standards while maintaining operational efficiency and safety margins in critical process control applications.

Power Generation and Energy Sector Applications

The power generation industry extensively utilizes bellows seal electric control valves in both conventional and renewable energy applications. In thermal power plants, these Electric Control Valve systems control steam flow, feedwater regulation, and cooling water circulation with exceptional reliability. Nuclear power facilities require absolute leak-tight performance for radioactive fluid handling, making bellows seal technology indispensable for reactor coolant systems and auxiliary circuits. The electric actuation provides fail-safe operation during emergency conditions, ensuring proper system shutdown and containment integrity. Renewable energy applications, including geothermal plants and concentrated solar power systems, benefit from the valve's ability to handle high-temperature working fluids and cycling conditions. The intelligent control capabilities enable optimal plant efficiency through precise flow modulation and integration with distributed control systems for automated plant operations.

Pharmaceutical and Biotechnology Manufacturing

The pharmaceutical industry demands the highest standards of product purity and contamination prevention, making bellows seal electric control valves essential for critical manufacturing processes. These Electric Control Valve systems prevent cross-contamination between batch processes and eliminate the risk of product adulteration through stem leakage. The smooth, crevice-free internal surfaces meet FDA and cGMP requirements for cleanability and validation. Biotechnology applications, including fermentation processes and cell culture systems, require precise control of sterile media flows while maintaining aseptic conditions. The electric actuation enables automated CIP (Clean-in-Place) and SIP (Sterilize-in-Place) procedures, reducing manual intervention and improving process consistency. Advanced materials such as electropolished stainless steel and specialized elastomers ensure compatibility with aggressive cleaning agents and sterilization processes, making these valves integral to modern pharmaceutical manufacturing operations.

Technology Comparison and Innovation Trends

Bellows Seal vs. Traditional Packing Technologies

The fundamental advantage of bellows seal electric control valves over traditional packing-based designs lies in their elimination of fugitive emissions and maintenance requirements. Conventional Electric Control Valve designs rely on packing materials such as PTFE, graphite, or elastomeric seals that require periodic adjustment and replacement due to wear and relaxation. The bellows technology provides a permanent metal-to-metal seal that maintains integrity throughout the valve's operational life without maintenance intervention. Comparative studies demonstrate that bellows seal valves achieve leakage rates below 10^-9 sccs helium, compared to 10^-6 sccs for premium packing systems. The electric actuation eliminates the need for pneumatic air supplies, reducing infrastructure requirements and improving response characteristics. Cost-benefit analyses indicate that while bellows seal valves require higher initial investment, the reduced maintenance costs, improved process efficiency, and regulatory compliance benefits provide superior total cost of ownership over the valve's service life.

Electric vs. Pneumatic Actuation Advantages

Electric actuation technology offers significant advantages over pneumatic systems in bellows seal control valve applications. Electric actuators provide precise positioning control without the lag and overshoot characteristics typical of pneumatic systems. The Electric Control Valve design eliminates the need for instrument air systems, reducing installation costs and improving reliability in remote locations. Electric actuators maintain position during power failures when equipped with battery backup systems, while pneumatic valves typically fail to predetermined positions. The higher torque output capabilities of electric actuators enable operation of larger valve sizes and higher pressure applications. Diagnostic capabilities built into electric actuators provide continuous monitoring of motor current, position feedback, and operational parameters, enabling predictive maintenance strategies. The integration with digital control systems allows for advanced control algorithms, including cascade control, feedforward compensation, and model predictive control strategies that optimize process performance and efficiency.

Emerging Technologies and Future Developments

The evolution of bellows seal electric control valve technology continues to advance through integration of digital technologies and smart manufacturing techniques. Industry 4.0 concepts are being implemented through IoT connectivity, enabling real-time monitoring of valve performance parameters and integration with cloud-based analytics platforms. Advanced materials research focuses on developing new bellows alloys with enhanced corrosion resistance and fatigue life. The Electric Control Valve industry is exploring additive manufacturing techniques for complex internal geometries that optimize flow characteristics and reduce pressure losses. Artificial intelligence algorithms are being developed for autonomous valve diagnostics, performance optimization, and predictive failure analysis. Future developments include wireless power transmission for valve actuation, advanced sensor integration for multivariable process monitoring, and self-healing material technologies that extend operational life. These innovations position bellows seal electric control valves at the forefront of industrial automation and process control technology advancement.

Conclusion

Bellows seal electric control valves represent the pinnacle of industrial flow control technology, combining leak-proof performance with intelligent automation capabilities. Their superior sealing technology, precise control characteristics, and extensive application versatility make them indispensable for modern industrial operations requiring zero-emission performance and reliable process control. As industries continue to prioritize safety, environmental compliance, and operational efficiency, these advanced valve systems will play an increasingly critical role in achieving these objectives.

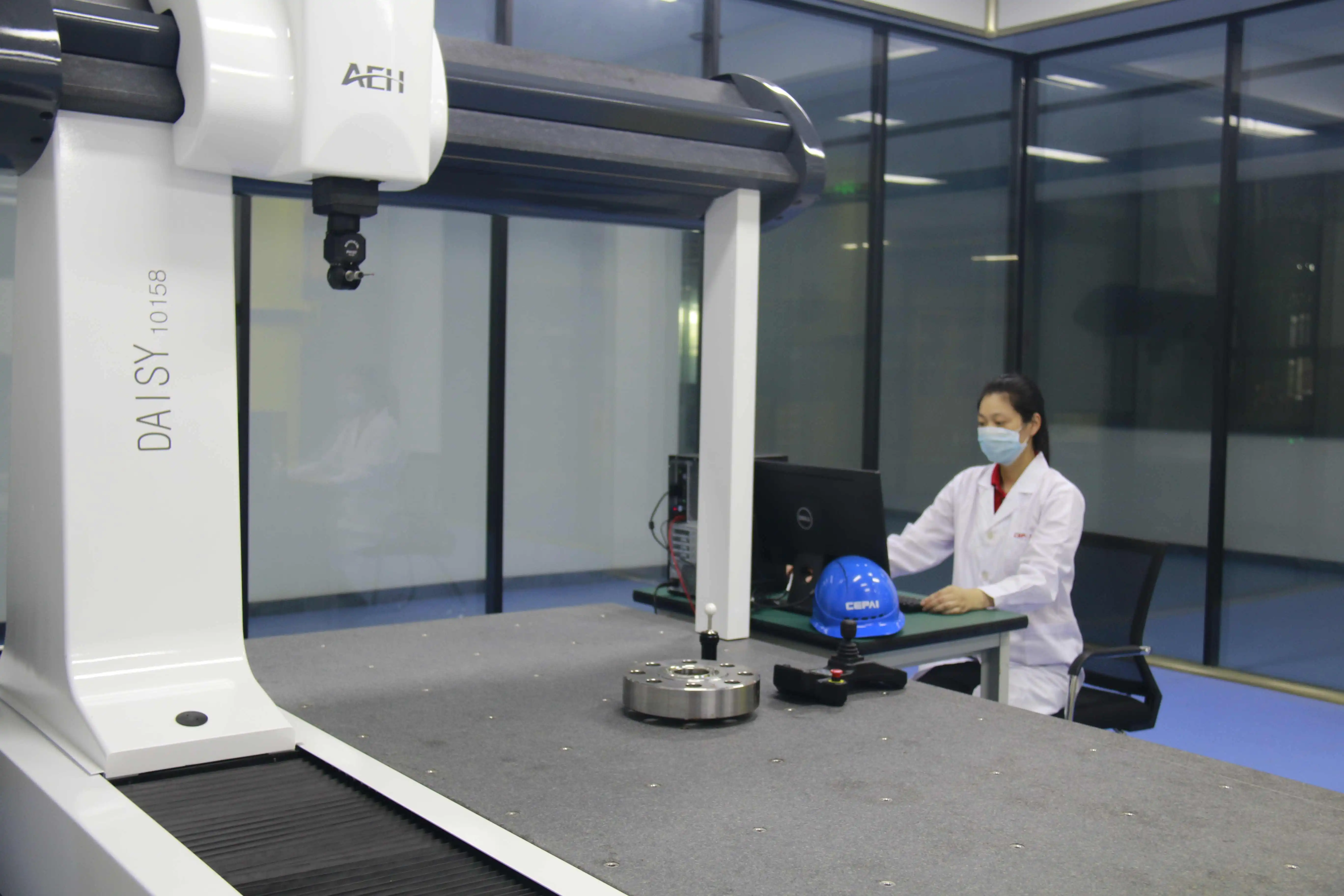

For industries seeking cutting-edge Electric Control Valve solutions, CEPAI Group Co., Ltd. stands as your premier China Electric Control Valve manufacturer and China Electric Control Valve supplier. With over 15 years of expertise in high-precision valve manufacturing, our intelligent production facilities ensure exceptional quality and reliability. As a leading China Electric Control Valve factory, we offer comprehensive China Electric Control Valve wholesale solutions with competitive Electric Control Valve prices. Our extensive range includes premium Electric Control Valve for sale with full technical support and worldwide service coverage. Experience the CEPAI advantage in precision engineering, intelligent manufacturing, and customer-focused solutions. Contact our expert team at cepai@cepai.com to discuss your specific requirements and discover how our advanced bellows seal electric control valves can optimize your industrial processes while ensuring zero-emission performance and regulatory compliance.

References

1. Smith, J.A., and Chen, L.M. "Advanced Bellows Seal Technologies in Industrial Control Valves: Design Principles and Performance Analysis." Journal of Industrial Process Control Engineering, 2023.

2. Rodriguez, M.P., Williams, R.K., and Thompson, D.L. "Electric Actuation Systems for High-Performance Control Valves: Comparative Study and Application Guidelines." International Review of Process Automation Technology, 2022.

3. Kumar, S., and Anderson, P.J. "Zero-Emission Valve Technologies in Chemical Processing: Bellows Seal Design and Material Selection Criteria." Chemical Engineering and Process Safety Journal, 2023.

4. Zhang, H.W., Mueller, K.F., and Johnson, M.R. "Smart Valve Technologies and Industry 4.0 Integration: Electric Control Valve Systems with Predictive Maintenance Capabilities." Industrial Automation and Control Systems Review, 2024.

_1745994800896.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI