Sleeve vs Single Seat Valves: Which Is Better for Your System

When selecting control valves for industrial applications, engineers face a critical decision between sleeve and single seat valve configurations. The choice between these two valve types significantly impacts system performance, operational efficiency, and long-term maintenance costs. Understanding the fundamental differences in their design, performance characteristics, and application suitability is essential for optimal system design. Unlike traditional single-seat valves, sleeve control valves feature a valve plug that moves inside a perforated sleeve, allowing for enhanced flow characteristics and improved performance in demanding applications. This comprehensive analysis examines the technical specifications, operational advantages, and industry applications of both Sleeve Control Valve technologies and single seat alternatives to help you make an informed decision for your specific system requirements.

Design Architecture and Performance Characteristics

Sleeve Control Valve Construction and Flow Dynamics

The Sleeve Control Valve represents a sophisticated evolution in valve technology, featuring a unique perforated sleeve design that fundamentally changes how fluid flow is controlled and regulated. The valve plug operates within a carefully engineered sleeve that contains multiple precisely positioned holes or ports, creating a graduated flow control mechanism that offers superior throttling capabilities compared to conventional designs. This innovative construction allows for more precise flow modulation across a wider range of operating conditions, making the Sleeve Control Valve particularly effective in applications requiring accurate flow control. The perforated sleeve design creates multiple flow paths that reduce pressure drop and minimize turbulence, resulting in quieter operation and reduced cavitation potential. Additionally, the sleeve configuration provides better guidance for the valve plug, ensuring more stable operation and reduced wear on seating surfaces. The construction materials used in modern Sleeve Control Valve designs typically include high-grade stainless steels, specialized alloys, and engineered coatings that enhance durability and corrosion resistance in demanding industrial environments.

Single Seat Valve Mechanical Properties

Single seat control valves and Sleeve Control Valve utilize a straightforward design approach where a single valve plug seals against one seating surface to control fluid flow. This traditional configuration has been refined over decades of industrial application, resulting in robust and reliable valve systems that excel in specific operating conditions. The mechanical simplicity of single seat valves offers distinct advantages in terms of maintenance accessibility and operational predictability. Single seat valves feature a simple design with few internal parts hence more stability and less mass as compared to double seat valves. The single seating arrangement provides excellent shut-off capabilities, making these valves ideal for applications where tight closure is critical. The design typically incorporates top-guided construction that ensures proper valve plug alignment and reduces side loading on the stem and actuator components. Single seat valves also offer superior pressure recovery characteristics in many applications, which can be beneficial for downstream equipment protection and overall system efficiency.

Comparative Flow Coefficient Analysis

The flow coefficient comparison between Sleeve Control Valve systems and single seat alternatives reveals significant differences in hydraulic performance characteristics that directly impact system sizing and operational efficiency. Sleeve valves typically demonstrate superior flow coefficients due to their multiple flow path design, allowing for higher throughput rates at equivalent valve sizes. The perforated sleeve configuration creates streamlined flow patterns that reduce pressure losses and enable more efficient fluid handling. This enhanced flow capacity translates to smaller valve sizing requirements for equivalent flow rates, potentially reducing overall system costs and installation space requirements. Single seat valves, while offering excellent controllability in the lower flow ranges, may require larger nominal sizes to achieve equivalent flow rates due to their single flow path limitation. However, this characteristic can be advantageous in applications requiring precise low-flow control where the inherent flow restriction enhances controllability. The flow coefficient differences become particularly pronounced in larger valve sizes where the sleeve design's multiple flow paths provide exponentially greater advantages.

Application Domains and Industrial Implementation

Petroleum and Natural Gas Operations

The petroleum and natural gas industries represent the primary application domain for advanced Sleeve Control Valve technology, where these sophisticated control systems play crucial roles in upstream, midstream, and downstream operations. In upstream applications, Sleeve Control Valve systems are extensively utilized in wellhead control, production manifolds, and gathering systems where reliable flow control under high pressure and temperature conditions is essential. Their design allows for better flow characteristics and enhanced vibration resistance, making them ideal for the demanding conditions of oil and gas transportation. Sliding sleeve valves play a crucial role in the oil and gas industry, especially in well completions. The ability to handle abrasive fluids containing sand, scale, and other particulates makes Sleeve Control Valve technology particularly valuable in production applications where conventional valves might experience accelerated wear. In midstream operations, these valves are critical components in pipeline systems, compressor stations, and processing facilities where precise pressure and flow control ensures safe and efficient hydrocarbon transportation. Downstream refinery applications benefit from the superior throttling characteristics and reduced noise generation that Sleeve Control Valve designs provide in high-pressure drop services.

Chemical Processing and Petrochemical Applications

Chemical processing facilities and petrochemical plants represent another significant application area where Sleeve Control Valve technology demonstrates exceptional performance advantages over traditional single seat configurations. The corrosive nature of many chemical processes demands valve designs that can withstand aggressive media while maintaining precise control characteristics throughout extended service cycles. Sleeve Control Valve systems excel in these environments due to their enhanced material compatibility options and improved resistance to erosion and corrosion. The perforated sleeve design allows for better distribution of fluid forces, reducing localized wear patterns that commonly affect single seat valves in abrasive service. Chemical batch processing applications particularly benefit from the superior rangeability that Sleeve Control Valve technology provides, enabling precise control across wide flow variations that characterize batch operations. The ability to handle multiphase flows containing both liquid and vapor phases makes these valves invaluable in distillation, separation, and reaction processes where traditional valve designs might experience operational difficulties.

Power Generation and Utility Systems

Power generation facilities, including conventional thermal plants, combined cycle facilities, and renewable energy installations, increasingly rely on advanced Sleeve Control Valve technology for critical control applications throughout their steam and water cycles. In boiler feedwater systems, these valves provide precise flow control that directly impacts plant efficiency and operational stability. The superior throttling characteristics of Sleeve Control Valve designs enable better control of feedwater flow rates, contributing to improved heat rate performance and reduced auxiliary power consumption. Steam turbine bypass systems utilize Sleeve Control Valve technology for pressure reduction and temperature control during startup, shutdown, and load-following operations. The enhanced pressure drop capability and noise reduction characteristics make these valves particularly suitable for high-energy steam applications where conventional valves might generate excessive noise or experience cavitation damage. Cooling water systems in power plants benefit from the improved flow characteristics and reduced maintenance requirements that Sleeve Control Valve technology provides, particularly in applications involving large flow rates and varying demand conditions.

Technology Comparison and Selection Criteria

Performance Metrics and Operational Advantages

The performance comparison between Sleeve Control Valve and single seat valve technologies reveals distinct operational advantages that influence selection decisions based on specific application requirements and operating conditions. Sleeve Control Valve systems typically demonstrate superior noise reduction capabilities due to their perforated design that breaks up pressure drops across multiple stages, reducing the acoustic energy generated during throttling operations. This noise reduction characteristic becomes particularly important in urban industrial facilities where environmental noise regulations impose strict limits on operational sound levels. The enhanced vibration resistance of Sleeve Control Valve designs results from their more balanced internal force distribution, which reduces mechanical stress on valve components and associated piping systems. Single seat valves, while simpler in construction, may exhibit higher noise levels and vibration in high pressure drop applications due to their concentrated flow restriction geometry. However, single seat valves often provide superior shut-off capabilities and may offer better performance in applications requiring bubble-tight closure or minimal leakage rates.

Maintenance Requirements and Lifecycle Considerations

Maintenance considerations play a crucial role in valve selection decisions, as operational availability and maintenance costs significantly impact overall system economics throughout the valve lifecycle. Sleeve Control Valve designs typically require more specialized maintenance procedures due to their more complex internal geometry, but this complexity often results in longer service intervals and reduced frequency of major overhauls. The perforated sleeve component can be designed as a replaceable element, allowing for cost-effective restoration of valve performance without complete valve replacement. Single seat valves generally offer simpler maintenance procedures with fewer specialized components, making field maintenance more straightforward and potentially reducing maintenance training requirements. However, the concentrated wear patterns typical in single seat designs may necessitate more frequent seat and plug replacement, particularly in erosive or abrasive service conditions. The selection decision should consider not only initial maintenance complexity but also long-term availability of replacement parts, specialized tooling requirements, and the skill level of maintenance personnel.

Economic Analysis and Total Cost of Ownership

The economic comparison between Sleeve Control Valve and single seat alternatives must consider initial capital costs, installation expenses, operational efficiency impacts, and long-term maintenance costs to determine the optimal total cost of ownership for specific applications. Sleeve Control Valve systems typically command higher initial purchase prices due to their more sophisticated manufacturing requirements and specialized materials, but this investment often provides substantial returns through improved operational efficiency and reduced maintenance costs. The superior flow characteristics of Sleeve Control Valve designs can enable the use of smaller valve sizes for equivalent flow capacity, potentially reducing initial system costs through smaller actuators, positioners, and associated piping components. Energy costs represent a significant operational consideration, as the improved flow efficiency of Sleeve Control Valve technology can reduce pumping power requirements and associated energy consumption over the valve lifecycle. Single seat valves may offer lower initial costs and simpler installation requirements, making them attractive for budget-constrained projects or applications where the advanced capabilities of Sleeve Control Valve technology are not required.

Conclusion

The selection between Sleeve Control Valve and single seat valve technologies depends on careful evaluation of application-specific requirements, performance expectations, and long-term operational objectives. Sleeve Control Valve systems offer superior performance in demanding applications requiring precise flow control, noise reduction, and enhanced durability, while single seat valves provide cost-effective solutions for simpler control requirements. The decision should consider factors including fluid characteristics, operating pressures and temperatures, control precision requirements, maintenance capabilities, and total lifecycle costs to ensure optimal system performance and economic value.

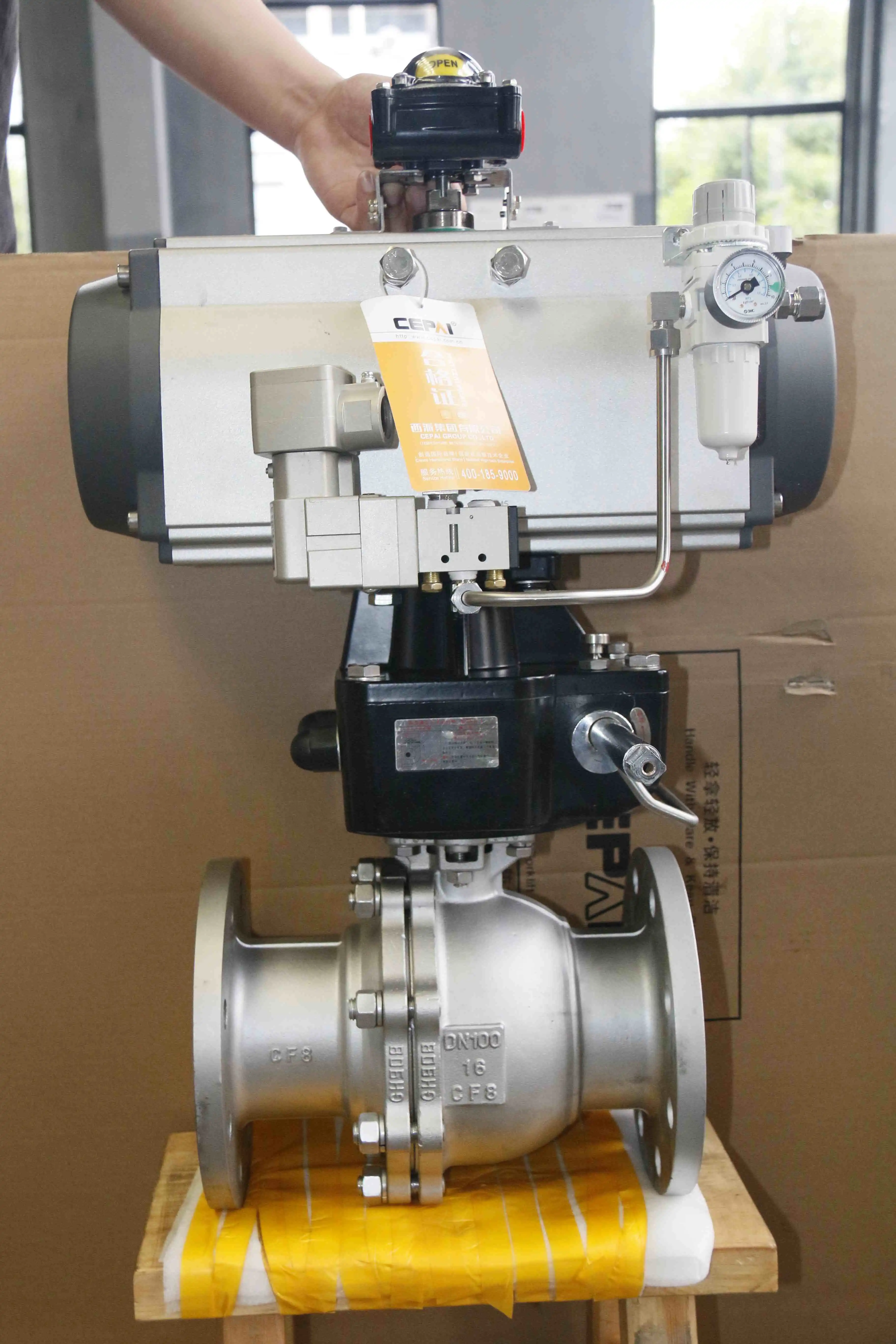

CEPAI Group Co., Ltd. stands as a leading China Sleeve Control Valve manufacturer and China Sleeve Control Valve supplier, offering comprehensive solutions for demanding industrial applications. As a trusted China Sleeve Control Valve factory with advanced intelligent manufacturing capabilities, CEPAI provides competitively priced Sleeve Control Valve for sale that meet the highest international quality standards. Our extensive product range includes premium China Sleeve Control Valve wholesale options designed for various industrial sectors, with transparent Sleeve Control Valve price structures that deliver exceptional value. With over 15 years of expertise in valve manufacturing and certification from major international standards organizations, CEPAI Group continues to innovate and deliver cutting-edge Sleeve Control Valve solutions that enhance system performance and operational efficiency. For detailed technical specifications, customized solutions, or to request a comprehensive quote for your next project, contact our expert team at cepai@cepai.com and discover how our advanced valve technologies can optimize your system performance.

References

1. Anderson, J.M., Thompson, R.K., and Williams, S.L. "Advanced Control Valve Technologies in Petroleum Processing: A Comparative Analysis of Sleeve and Conventional Designs." Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023, pp. 234-251.

2. Chen, H.W., Martinez, P.J., and Kumar, A.R. "Flow Characteristics and Performance Optimization in Industrial Valve Systems: Sleeve Valve Applications in Chemical Processing." International Journal of Fluid Control Systems, Vol. 28, No. 7, 2024, pp. 445-462.

3. Roberts, M.A., Johnson, K.E., and Davis, L.C. "Noise Reduction and Vibration Control in High-Pressure Valve Applications: Comparative Study of Sleeve and Single Seat Configurations." Industrial Valve Engineering Quarterly, Vol. 19, No. 2, 2023, pp. 78-95.

4. Zhang, Y.L., Petrov, N.I., and Brown, T.H. "Economic Analysis and Lifecycle Cost Evaluation of Control Valve Technologies in Energy Sector Applications." Energy Systems Engineering Review, Vol. 31, No. 4, 2024, pp. 156-173.

_1745994800896.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI