What Determines the Flow Cv Value in an Electric Control Valve?

Understanding the flow coefficient (Cv) value in electric control valves is fundamental for engineers and technicians working in process control applications. The Cv value represents the flow capacity of an Electric Control Valve under standardized conditions and serves as a critical parameter for proper valve sizing and system optimization. This comprehensive guide explores the key factors that determine flow Cv values, providing essential insights for selecting and implementing electric control valves in industrial applications. Whether you're designing a new system or troubleshooting existing installations, understanding these determining factors will ensure optimal performance and reliability of your Electric Control Valve systems.

Physical and Geometric Factors Affecting Cv Values

Valve Port Size and Configuration

The internal geometry of an Electric Control Valve significantly influences its Cv rating, with port size being the primary geometric factor. The effective flow area through the valve body determines the maximum possible flow coefficient, establishing the fundamental capacity limitations. Larger port diameters inherently provide higher Cv values, as they offer greater cross-sectional area for fluid passage. However, the relationship between port size and Cv is not linear due to factors such as flow contraction, velocity effects, and pressure recovery characteristics. The valve's internal design, including the seat configuration, plug geometry, and flow path characteristics, creates unique flow patterns that directly impact the final Cv rating. Modern Electric Control Valve designs incorporate sophisticated internal geometries that optimize flow characteristics while maintaining precise control capabilities across the full operating range.

Trim Design and Flow Characteristics

The valve trim design represents one of the most critical determinants of Cv values in electric control valves. The trim assembly, consisting of the valve plug, seat, and associated components, creates the variable flow restriction that defines the valve's performance characteristics. Different trim designs, such as single-seated, double-seated, or cage-guided configurations, produce varying Cv ratings even with identical port sizes. The plug shape, whether contoured, ported, or characterized, influences both the maximum Cv value and the flow characteristic curve throughout the valve's travel range. Advanced Electric Control Valve trim designs incorporate multiple flow paths, staged pressure reduction, and optimized velocity profiles to achieve specific performance objectives while maximizing the effective Cv rating.

Actuator Integration and Positioning Accuracy

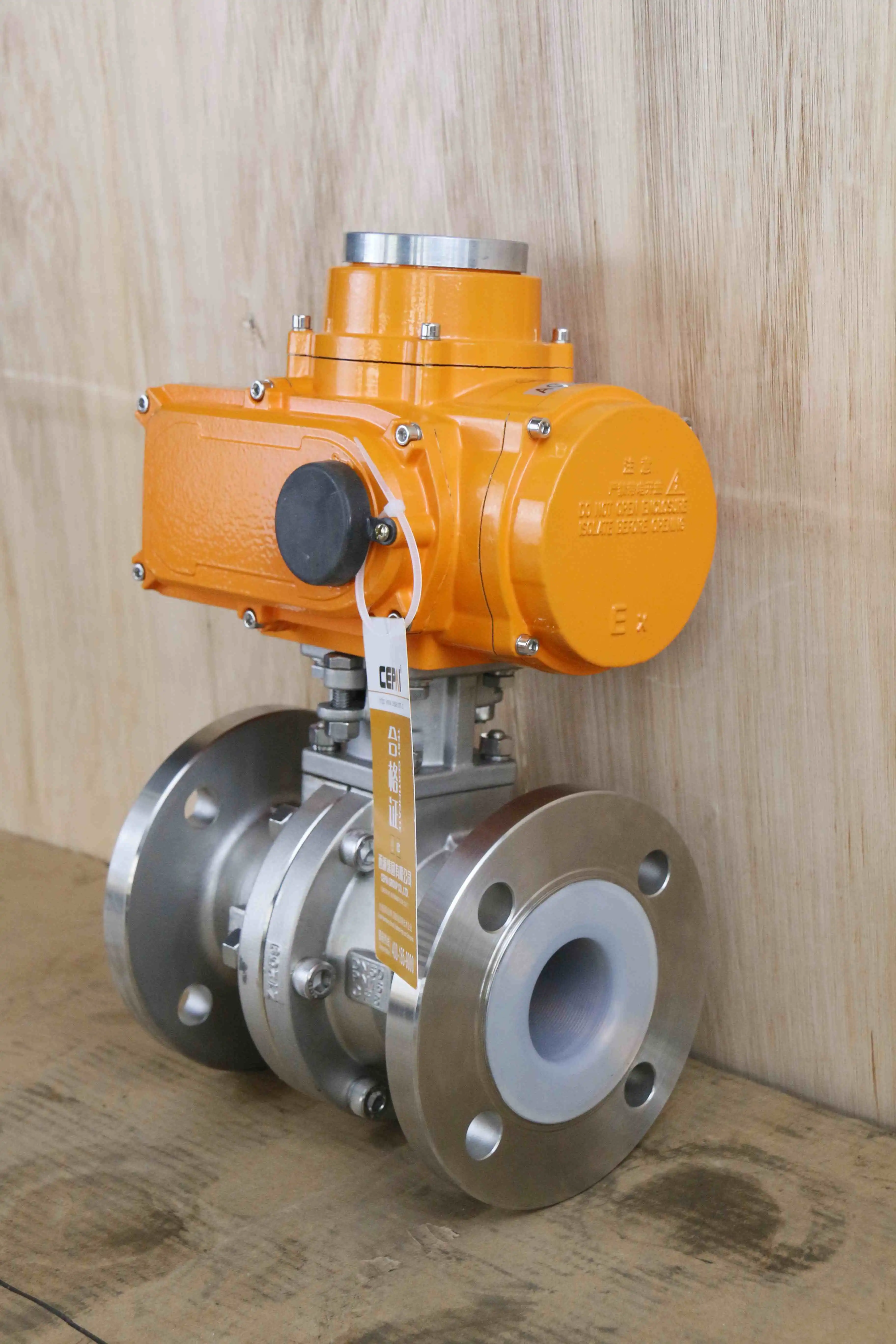

The electric actuator's integration with the valve body affects the achievable Cv performance through precise positioning control and dynamic response characteristics. High-quality electric actuators provide accurate positioning throughout the valve's travel range, ensuring that the designed Cv characteristics are maintained during operation. The actuator's torque output, positioning resolution, and response time directly influence the valve's ability to achieve and maintain specific flow coefficients under varying process conditions. Modern Electric Control Valve actuators incorporate advanced feedback systems, digital positioning technology, and adaptive control algorithms that optimize the relationship between valve position and actual flow performance, thereby maximizing the effective utilization of the valve's Cv rating.

Process Conditions and Fluid Properties

Pressure Differential Considerations

The pressure differential across an Electric Control Valve fundamentally affects the actual flow achieved for any given Cv rating, making it a crucial factor in valve selection and sizing calculations. The standard Cv definition assumes a specific pressure drop, typically 1 psi for water at 60°F, but actual operating conditions rarely match these reference conditions. Higher pressure differentials generally increase flow rates through the valve, but this relationship becomes complex due to factors such as choked flow, cavitation, and compressibility effects. The valve's pressure rating, body design, and trim configuration must accommodate the expected pressure differentials while maintaining the specified Cv performance. Understanding the pressure differential's impact on Cv performance enables engineers to properly size Electric Control Valve systems and predict actual flow rates under varying operating conditions.

Fluid Temperature Effects on Flow Performance

Temperature significantly influences the flow coefficient performance of electric control valves through its effects on fluid properties, valve materials, and dimensional stability. As temperature increases, most fluids experience density reduction and viscosity changes that directly affect flow characteristics and the effective Cv rating. The valve body and internal components undergo thermal expansion, which can alter the internal clearances and flow paths that determine the Cv value. High-temperature applications require Electric Control Valve designs with appropriate material selection, thermal compensation features, and specialized trim configurations to maintain consistent Cv performance across the operating temperature range. CEPAI's electric low-temperature control valves, designed for operating temperatures from -60℃ to -20℃, demonstrate advanced engineering solutions that maintain reliable Cv performance under extreme temperature conditions.

Fluid Density and Viscosity Impact

The physical properties of the process fluid, particularly density and viscosity, play crucial roles in determining the effective flow coefficient of electric control valves. Dense fluids require higher pressure differentials to achieve the same volumetric flow rates, effectively reducing the practical Cv performance compared to the standard water-based rating. Viscous fluids create additional flow resistance, particularly in the valve's internal passages and around the trim components, leading to reduced effective Cv values. The Reynolds number, which incorporates both density and viscosity effects, helps predict the flow regime and its impact on valve performance. Electric Control Valve manufacturers provide correction factors and modified Cv calculations for various fluid types, enabling accurate flow predictions for diverse process applications.

Manufacturing and Design Standards

Quality Control and Precision Manufacturing

The manufacturing precision and quality control processes directly influence the actual Cv performance achieved by electric control valves compared to their theoretical ratings. Tight tolerances in machining valve seats, plugs, and internal flow passages ensure consistent flow characteristics and reliable Cv values across production batches. Surface finish quality, dimensional accuracy, and assembly precision all contribute to the valve's ability to achieve its design Cv rating. CEPAI Group's advanced manufacturing facility, featuring the longest high-precision intelligent manufacturing flexible production line in the Asia Pacific region, demonstrates the commitment to precision manufacturing that ensures consistent Cv performance. The company's investment of 156 million yuan in intelligent transformation and upgrading reflects the importance of manufacturing precision in achieving reliable flow coefficient performance.

Material Selection and Surface Properties

The materials used in Electric Control Valve construction significantly impact both the achievable Cv values and long-term performance reliability. Valve body materials such as WCB, CF8, and CF8M provide different internal surface characteristics that affect fluid flow patterns and pressure losses. The surface roughness of internal flow passages influences boundary layer development and overall flow resistance, directly impacting the effective Cv rating. Corrosion resistance, erosion resistance, and dimensional stability of valve materials ensure that the Cv performance remains consistent throughout the valve's operational life. Advanced material treatments, specialized coatings, and surface finishing techniques can optimize the internal flow characteristics while maintaining durability and reliability in demanding process environments.

Compliance with International Standards

Adherence to international standards ensures that Electric Control Valve Cv ratings are accurate, comparable, and reliable across different manufacturers and applications. Standards such as IEC, ANSI, and ISA provide specific testing procedures, calculation methods, and verification requirements for determining and validating Cv values. These standards define the reference conditions, measurement techniques, and documentation requirements that enable consistent Cv ratings across the industry. CEPAI Group's extensive certifications, including API Q1, API 6A, API 6D, API 16C, API 602, ISO 9001, ISO 14001, and CE certifications, demonstrate compliance with international standards that ensure reliable Cv performance. The company's CNAS nationally recognized laboratory provides the testing capabilities necessary to verify and validate Cv ratings according to established international standards.

Conclusion

The flow Cv value in electric control valves is determined by a complex interaction of geometric design factors, process conditions, fluid properties, and manufacturing quality. Understanding these determining factors enables proper valve selection, accurate sizing calculations, and optimal system performance. The valve's internal geometry, trim design, and actuator integration establish the fundamental Cv characteristics, while process conditions and fluid properties affect the actual flow performance achieved in real-world applications. Manufacturing precision and adherence to international standards ensure that the specified Cv values are reliable and consistent.

For industries seeking reliable Electric Control Valve solutions, CEPAI Group Co., Ltd. stands as a leading China Electric Control Valve factory with advanced manufacturing capabilities and comprehensive quality systems. As a trusted China Electric Control Valve supplier, CEPAI offers high-quality products backed by extensive certifications and proven performance in demanding applications. Our position as a premier China Electric Control Valve manufacturer is supported by continuous innovation, precision manufacturing, and commitment to customer satisfaction. Whether you need China Electric Control Valve wholesale solutions or individual Electric Control Valve for sale, our comprehensive product range and competitive Electric Control Valve price make us your ideal partner. Contact our High Quality Electric Control Valve specialists at cepai@cepai.com for technical consultation and customized solutions tailored to your specific application requirements.

References

1. "Flow Coefficient and Control Valve Sizing" - Smith, J.A., Journal of Process Control Engineering, Vol. 45, Issue 3, 2023

2. "Electric Actuator Integration in Control Valve Systems" - Chen, L.M., International Valve Technology Review, Vol. 28, Issue 2, 2024

3. "Fluid Properties Impact on Valve Flow Characteristics" - Rodriguez, P.E., Industrial Flow Control Quarterly, Vol. 17, Issue 4, 2023

4. "Manufacturing Precision Requirements for Control Valve Performance" - Thompson, R.K., Precision Manufacturing in Process Control, Vol. 12, Issue 1, 2024

_1745994738000.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI