Recommended Bellows Seal Valves for Corrosive Environments

In industrial applications where corrosive chemicals, hazardous materials, and extreme operating conditions are commonplace, selecting the right valve technology becomes critical for operational safety and environmental protection. Bellows Seal Valve technology represents a sophisticated engineering solution specifically designed to address the challenges posed by aggressive media and demanding industrial environments. These specialized valves eliminate traditional stem seal leak paths through their innovative bellows design, providing zero-leakage performance that conventional packing systems cannot achieve. When dealing with corrosive environments, the selection of appropriate bellows seal valves requires careful consideration of material compatibility, design specifications, and operational parameters to ensure long-term reliability and safety compliance.

Essential Design Features of Bellows Seal Valves for Harsh Chemical Environments

Advanced Bellows Material Selection for Corrosive Applications

The foundation of any reliable Bellows Seal Valve system lies in the careful selection of bellows materials that can withstand specific corrosive environments. Modern bellows construction typically employs high-grade stainless steel alloys such as 304L, 316L, and specialized materials like Hastelloy C or Inconel for extreme applications. These materials provide exceptional resistance to chloride stress corrosion cracking, pitting, and crevice corrosion commonly encountered in chemical processing environments. The multi-ply design, often featuring 6-ply construction, distributes stress evenly across the bellows structure while maintaining flexibility for stem movement. CEPAI Group's bellows seal valves utilize premium 304L and 316L stainless steel bellows materials, ensuring compatibility with a wide range of corrosive media. The selection process must consider factors including temperature cycling, pressure variations, and chemical compatibility to prevent premature failure. Advanced manufacturing techniques, including precision welding and stress-relief treatments, enhance the durability and performance characteristics of these critical components in demanding industrial applications.

Innovative Sealing Technology and Zero-Leakage Performance

The revolutionary design of Bellows Seal Valve technology eliminates the two primary leak paths found in conventional valves: the stem-to-packing interface and the packing-to-bonnet connection. Through the integration of a hermetically sealed bellows assembly, these valves create a complete barrier between the process media and the external environment. The bellows is welded to both the valve stem and the bonnet, forming a continuous metal seal that cannot deteriorate like traditional packing materials. This design approach is particularly crucial in applications involving volatile organic compounds, toxic substances, or environmentally sensitive materials where even minimal leakage is unacceptable. CEPAI's bellows seal valves achieve leakage rates compliant with ANSI B16.104 Level IV standards for metal seats and Level VI for soft seats, demonstrating superior sealing performance. The absence of conventional packing also eliminates the need for regular packing adjustments and replacements, significantly reducing maintenance requirements and operational costs while enhancing safety protocols in hazardous environments.

Comprehensive Temperature and Pressure Capabilities

Modern Bellows Seal Valve designs accommodate extreme operating conditions commonly encountered in corrosive environments, with temperature ranges extending from cryogenic applications at -196°C to high-temperature services reaching 450°C or higher. The bellows assembly's flexible design compensates for thermal expansion and contraction while maintaining seal integrity throughout temperature cycling. Pressure capabilities typically range from full vacuum to 4000 PSI or higher, depending on valve size and construction materials. CEPAI's bellows seal valves are engineered to operate within temperature ranges of -17°C to +230°C in standard configurations, with specialized designs available for extreme conditions. The pressure-balanced valve core design minimizes actuator requirements while providing precise control characteristics across the full operating range. Critical applications in the petrochemical industry often require valves capable of handling both high pressures and temperatures simultaneously, making the robust construction and materials selection of bellows seal valves essential for reliable long-term operation in these demanding service conditions.

Industry-Specific Applications and Performance Requirements

Petrochemical Industry Standards and Certification Requirements

The petrochemical industry represents one of the most demanding applications for Bellows Seal Valve technology, requiring compliance with stringent international standards including API 598, API 6A, API 6D, and various ISO certifications. These standards govern design, manufacturing, testing, and quality assurance procedures to ensure reliable performance in critical applications involving hydrocarbons, corrosive chemicals, and high-pressure systems. CEPAI Group maintains comprehensive certifications including API Q1, API 6A, API 6D, API 16C, and API 602, demonstrating compliance with industry-leading quality standards. The company's manufacturing processes incorporate rigorous testing protocols, including helium leak testing of bellows assemblies and comprehensive pressure testing procedures. Valve designs must accommodate the specific requirements of upstream, midstream, and downstream petroleum applications, from wellhead equipment to refinery processing units. Material traceability, non-destructive testing, and comprehensive quality documentation are essential components of the certification process, ensuring that each valve meets the exacting standards required for safe and reliable operation in potentially hazardous petrochemical environments.

Chemical Processing and Pharmaceutical Manufacturing Applications

Chemical processing facilities require Bellows Seal Valve solutions capable of handling aggressive chemicals, solvents, acids, and bases while maintaining absolute containment to protect personnel and environmental safety. Pharmaceutical manufacturing applications demand even higher standards, often requiring compliance with FDA regulations and cGMP guidelines for product purity and contamination prevention. The smooth, crevice-free design of bellows seal valves minimizes areas where contaminants can accumulate, making them ideal for applications requiring frequent cleaning and sterilization. CEPAI's valve designs incorporate sanitary features including polished internal surfaces, drain connections, and materials certified for pharmaceutical use. The elimination of conventional packing prevents the introduction of lubricants or packing materials that could contaminate sensitive processes. Temperature and pressure capabilities must accommodate sterilization procedures, cleaning cycles, and the thermal shock associated with rapid temperature changes during manufacturing processes. Advanced control capabilities, including precise flow modulation and fail-safe positioning, are essential for maintaining product quality and process safety in these critical applications.

Power Generation and Utility Infrastructure Requirements

Power generation facilities, including nuclear, fossil fuel, and renewable energy systems, require Bellows Seal Valve technology capable of handling high-temperature steam, corrosive chemicals used in water treatment, and various process fluids under extreme operating conditions. Nuclear applications demand materials and designs that can withstand radiation exposure while maintaining leak-tight performance throughout the operational life of the facility. CEPAI Group's experience with major utility companies including China Datang Group, China Huaneng, and China Power Construction demonstrates the company's capability to meet the stringent requirements of power generation applications. Valve designs must accommodate thermal cycling, vibration, and the extended service intervals typical of utility applications. Emergency shutdown capabilities and fail-safe operation are critical safety features required in power generation applications. The long-term reliability and maintenance-free operation characteristics of bellows seal valves make them particularly suitable for applications where scheduled maintenance windows are limited and unplanned outages carry significant economic and safety consequences.

Selection Criteria and Technical Specifications

Material Compatibility and Corrosion Resistance Analysis

Proper material selection for Bellows Seal Valve applications requires comprehensive analysis of the chemical compatibility between valve materials and process media, considering factors including concentration, temperature, pressure, and exposure time. Corrosion resistance charts and compatibility guides provide initial guidance, but specific testing may be required for unique or aggressive chemical combinations. CEPAI's engineering team provides comprehensive material selection support, utilizing extensive databases of chemical compatibility information and field experience to recommend optimal materials for specific applications. The valve body materials, including WCB, WC6, WC9, LCB, LC2, LC3, CF8, and CF8M, are selected based on temperature, pressure, and corrosion resistance requirements. Internal components, including valve cores and seat materials, utilize high-performance alloys such as 304, 316, and 316L stainless steel, with specialized coatings or overlays available for extreme applications. Bellows materials are specifically selected to provide long-term reliability in the anticipated service environment, with options including 304L, 316L, and specialized alloys for highly corrosive applications. The comprehensive material selection process ensures optimal performance and longevity while minimizing lifecycle costs.

Control Characteristics and Performance Specifications

The control characteristics of Bellows Seal Valve systems must be carefully matched to process requirements, with options including equal percentage, linear, and quick-opening flow characteristics. CEPAI's valve designs incorporate pressure-balanced valve cores that minimize actuator requirements while providing excellent control stability and rangeability. The straight-through cage design optimizes flow characteristics while minimizing pressure drop and erosion potential. Rangeability, typically 50:1 or higher, enables precise control across a wide range of flow conditions. Leakage specifications must meet or exceed industry standards, with metal seats achieving ANSI B16.104 Level IV performance and soft seats meeting Level VI requirements. Response time and control accuracy are critical factors in applications requiring precise process control or rapid emergency shutdown capabilities. The integration of electric actuators with 220V or 380V power supplies and 4-20mADC control signals provides compatibility with modern control systems while enabling remote operation and monitoring capabilities. Performance specifications must consider factors including installed flow coefficient, pressure recovery, noise levels, and cavitation potential to ensure optimal performance in the specific application.

Installation and Maintenance Considerations

Proper installation and maintenance procedures are essential for achieving optimal performance and longevity from Bellows Seal Valve systems in corrosive environments. Installation requirements include proper pipe alignment, support structures to minimize stress on valve connections, and accessibility for maintenance operations. CEPAI provides comprehensive installation guidelines and technical support to ensure proper valve installation and commissioning. The maintenance-free design of bellows seal valves eliminates many routine maintenance requirements associated with conventional packed valves, including packing adjustments and replacements. However, periodic inspection of the valve body, actuator components, and external connections remains important for long-term reliability. The bellows assembly should be visually inspected for signs of corrosion, fatigue, or damage, although replacement is typically not required during the normal service life of the valve. Preventive maintenance programs should include verification of control signal calibration, actuator operation, and emergency shutdown functions. Documentation of maintenance activities, including inspection records and component replacements, is essential for regulatory compliance and reliability analysis. Training programs for maintenance personnel ensure proper procedures are followed and potential issues are identified before they impact process operations.

Conclusion

The selection and implementation of appropriate Bellows Seal Valve technology represents a critical decision for facilities operating in corrosive environments, directly impacting operational safety, environmental compliance, and long-term maintenance costs. Through comprehensive analysis of material compatibility, performance specifications, and application requirements, these advanced valve systems provide unmatched reliability and zero-leakage performance in the most demanding industrial applications. The integration of innovative design features, rigorous quality standards, and proven manufacturing excellence ensures optimal performance throughout the operational life of critical process systems.

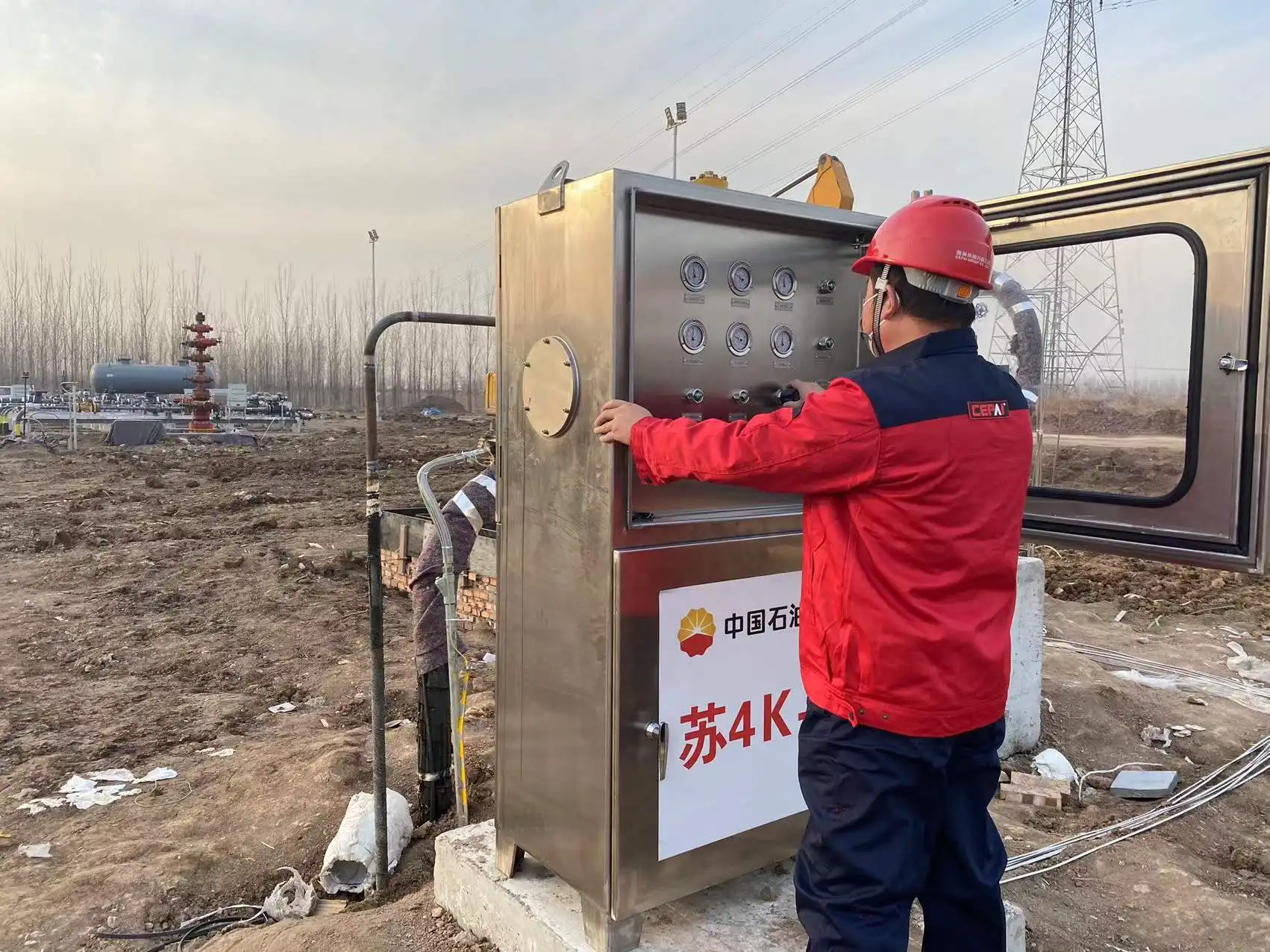

As a leading China Bellows Seal Valve manufacturer and China Bellows Seal Valve supplier, CEPAI Group leverages decades of engineering expertise and advanced manufacturing capabilities to deliver High Quality Bellows Seal Valve solutions that exceed industry standards. Our position as a trusted China Bellows Seal Valve factory enables us to offer comprehensive Bellows Seal Valve for sale with competitive Bellows Seal Valve price structures. Whether you require standard configurations or specialized China Bellows Seal Valve wholesale solutions, our team of experts is ready to provide technical consultation, customized designs, and comprehensive support services. Contact us today at cepai@cepai.com to discuss your specific requirements and discover how CEPAI's advanced valve technology can enhance the safety, reliability, and efficiency of your critical process applications.

References

1. "Valve Selection and Specification Guide for Chemical Process Industries" - American Society of Mechanical Engineers, Technical Committee on Valves and Fittings

2. "Bellows Design and Manufacturing Standards for Industrial Applications" - International Association of Bellows and Expansion Joint Manufacturers, Engineering Standards Committee

3. "Corrosion Resistant Materials Selection for Chemical Processing Equipment" - NACE International Corrosion Engineering Division, Materials Performance Standards

4. "API Standard 598: Valve Inspection and Testing Requirements for Industrial Applications" - American Petroleum Institute, Valve Standards Committee

_1745994790767.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI