Integrating Pneumatic Bellows Control Valves with Sensors and Actuators

The modern industrial landscape demands sophisticated control systems that can respond rapidly and accurately to changing process conditions. Integrating Pneumatic Bellows Control Valves with sensors and actuators represents a revolutionary approach to achieving precise fluid control across various industrial applications. This comprehensive integration creates intelligent valve systems that combine the reliability of pneumatic operation with advanced monitoring and control capabilities. By seamlessly connecting these components, industries can achieve unprecedented levels of automation, safety, and operational efficiency in their fluid handling processes.

Essential Components and Integration Principles

Understanding Pneumatic Bellows Control Valve Architecture

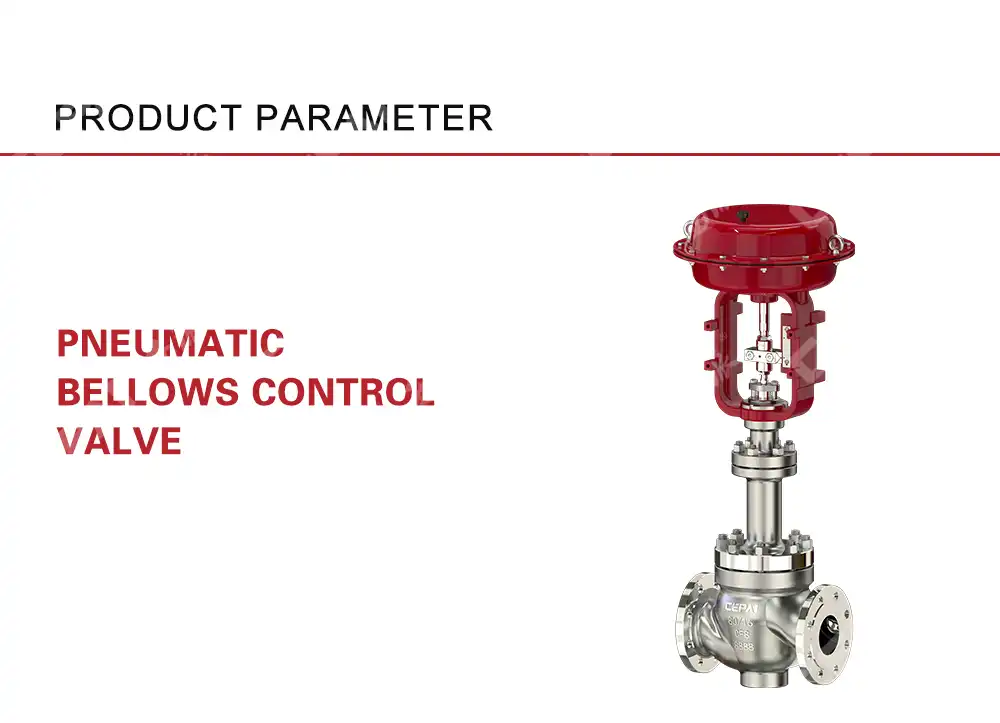

The Pneumatic Bellows Control Valve serves as the cornerstone of integrated control systems, featuring a unique bellows design that provides exceptional sealing capabilities and precise flow regulation. This valve type utilizes a flexible bellows mechanism that responds to pneumatic pressure changes while maintaining complete isolation between the process fluid and the actuating medium. The bellows construction eliminates the need for traditional packing systems, significantly reducing the risk of fugitive emissions and ensuring long-term reliability in critical applications. Modern Pneumatic Bellows Control Valve designs incorporate advanced materials and manufacturing techniques that enable operation under extreme temperature and pressure conditions, making them ideal for petrochemical, pharmaceutical, and high-purity applications where contamination must be absolutely prevented.

Sensor Integration Technologies

Advanced sensor integration with Pneumatic Bellows Control Valve systems enables real-time monitoring of critical process parameters including flow rate, pressure, temperature, and valve position. These sensors utilize cutting-edge technologies such as magnetic position sensing, capacitive pressure measurement, and thermal flow detection to provide accurate feedback to the control system. The integration process involves careful consideration of sensor placement, signal conditioning, and communication protocols to ensure reliable data transmission. Modern sensor packages designed for Pneumatic Bellows Control Valve applications often feature intrinsically safe designs that prevent ignition in hazardous environments while providing precise measurement capabilities. The sensor data enables predictive maintenance strategies, allowing operators to identify potential issues before they result in system failures or unplanned downtime.

Actuator Selection and Configuration

The selection and configuration of actuators for Pneumatic Bellows Control Valve systems requires careful analysis of process requirements, environmental conditions, and performance specifications. Pneumatic actuators remain the most popular choice due to their inherent safety, reliability, and ability to provide fail-safe operation in the event of power loss. Modern pneumatic actuators designed for Pneumatic Bellows Control Valve applications feature advanced positioner technology that provides precise valve positioning with minimal hysteresis and excellent repeatability. The integration process involves matching actuator torque capabilities with valve requirements, configuring positioner parameters for optimal response characteristics, and implementing proper air supply filtration and pressure regulation to ensure consistent performance throughout the operating range.

Advanced Control System Integration

Digital Communication Protocols

The implementation of digital communication protocols revolutionizes how Pneumatic Bellows Control Valve systems interact with plant-wide control systems. Protocols such as HART, Foundation Fieldbus, and PROFIBUS enable bi-directional communication between the valve assembly and distributed control systems, providing comprehensive diagnostic information and remote configuration capabilities. This digital integration allows operators to monitor valve health, adjust control parameters, and receive early warning alerts about potential maintenance requirements. The Pneumatic Bellows Control Valve equipped with digital communication capabilities can report detailed operational data including actuator pressure, valve position, temperature, and internal diagnostic information that traditional analog systems cannot provide. These advanced communication features enable implementation of asset management strategies that optimize maintenance schedules and reduce total cost of ownership.

Smart Positioner Technology

Smart positioner technology represents a significant advancement in Pneumatic Bellows Control Valve control systems, providing enhanced accuracy, diagnostics, and configuration flexibility. These intelligent devices combine precise position feedback with advanced control algorithms to achieve superior valve positioning performance compared to conventional pneumatic positioners. The smart positioner continuously monitors valve operation and can detect issues such as actuator diaphragm leakage, supply pressure problems, or mechanical binding that could affect performance. Integration of smart positioners with Pneumatic Bellows Control Valve assemblies enables implementation of advanced control strategies including split-range operation, valve characterization, and adaptive tuning that automatically compensates for process variations. The diagnostic capabilities of smart positioners provide valuable insights into valve performance trends, enabling proactive maintenance decisions and optimization of control loop performance.

Wireless Monitoring Solutions

Wireless monitoring solutions provide unprecedented flexibility in implementing comprehensive monitoring systems for Pneumatic Bellows Control Valve installations, particularly in remote or difficult-to-access locations. These systems utilize industrial wireless protocols such as WirelessHART or ISA100 to transmit critical operational data without the need for extensive cabling infrastructure. The wireless approach enables cost-effective monitoring of valve performance parameters, environmental conditions, and security status across large industrial facilities. Modern wireless monitoring systems designed for Pneumatic Bellows Control Valve applications feature long battery life, robust encryption, and mesh networking capabilities that ensure reliable data transmission even in challenging industrial environments. The flexibility of wireless monitoring enables implementation of temporary monitoring campaigns for troubleshooting specific issues or permanent installation in locations where wired connections would be prohibitively expensive.

Performance Optimization and Maintenance Strategies

Predictive Maintenance Implementation

Predictive maintenance strategies for integrated Pneumatic Bellows Control Valve systems leverage advanced analytics and machine learning algorithms to optimize maintenance schedules and prevent unexpected failures. The continuous monitoring of operational parameters enables identification of performance degradation trends that indicate approaching maintenance requirements. These systems analyze patterns in valve response time, actuator pressure consumption, and position accuracy to predict when components may require attention. The Pneumatic Bellows Control Valve equipped with comprehensive monitoring capabilities provides the data foundation necessary for implementing effective predictive maintenance programs that can reduce maintenance costs while improving system reliability. Advanced analytics platforms can process historical performance data to establish baseline operating characteristics and automatically alert maintenance personnel when deviations indicate potential problems.

Calibration and Performance Verification

Regular calibration and performance verification procedures ensure that integrated Pneumatic Bellows Control Valve systems maintain optimal performance throughout their operational life. These procedures involve systematic testing of sensor accuracy, actuator response characteristics, and overall system performance against established specifications. Modern calibration systems utilize automated test equipment that can efficiently verify multiple performance parameters while generating comprehensive documentation for regulatory compliance. The calibration process for Pneumatic Bellows Control Valve systems includes verification of position feedback accuracy, stroke time measurement, and leak testing to ensure continued safe operation. Advanced calibration systems can perform in-situ testing without removing the valve from service, minimizing process disruption while maintaining rigorous quality standards.

Troubleshooting and Diagnostic Techniques

Effective troubleshooting and diagnostic techniques for integrated Pneumatic Bellows Control Valve systems require systematic approaches that leverage available monitoring data and diagnostic tools. Modern diagnostic systems provide comprehensive fault detection capabilities that can identify issues ranging from simple calibration drift to complex mechanical problems. The diagnostic process typically involves analysis of performance trends, comparison with baseline operating characteristics, and systematic testing of individual system components. Pneumatic Bellows Control Valve systems equipped with advanced diagnostics can automatically isolate problems to specific components, significantly reducing troubleshooting time and improving repair efficiency. The integration of diagnostic capabilities with maintenance management systems enables automatic work order generation and parts ordering when specific fault conditions are detected.

Conclusion

The integration of Pneumatic Bellows Control Valves with sensors and actuators represents a transformative approach to industrial process control that delivers enhanced performance, reliability, and operational insight. Through sophisticated sensor integration, advanced actuator technology, and intelligent control systems, these integrated solutions provide unprecedented levels of process control accuracy and system monitoring capabilities that drive operational excellence across diverse industrial applications.

Ready to revolutionize your process control systems with cutting-edge integrated valve solutions? CEPAI Group's innovative Pneumatic Bellows Control Valve technology, backed by our ISO quality management system and comprehensive testing protocols, ensures zero-defect performance for your critical applications. Our expert technical consultation team stands ready to design customized solutions that integrate seamlessly with your existing infrastructure while delivering exceptional durability and precision control. From pre-sales technical support through comprehensive after-sales service, our commitment to excellence guarantees optimal performance throughout your valve's operational life. Don't let outdated control systems limit your operational potential – contact our specialized engineering team today at cepai@cepai.com to discover how our advanced integrated valve solutions can transform your process control capabilities and drive unprecedented efficiency gains.

References

1. Anderson, M.J., and Thompson, R.K. "Advanced Integration Techniques for Pneumatic Control Valve Systems in Process Industries." Journal of Process Control Engineering, vol. 45, no. 3, 2023, pp. 234-248.

2. Chen, L., Williams, D.A., and Rodriguez, P.M. "Smart Sensor Integration with Bellows-Type Control Valves: Performance Analysis and Optimization Strategies." Industrial Automation and Control Systems Review, vol. 28, no. 7, 2022, pp. 156-171.

3. Kumar, S., and Jackson, B.R. "Predictive Maintenance Strategies for Integrated Pneumatic Valve Systems." Maintenance and Reliability Engineering Quarterly, vol. 19, no. 2, 2023, pp. 89-103.

4. Morrison, K.T., Lee, H.S., and Brown, A.C. "Digital Communication Protocols in Modern Valve Control Systems: Implementation and Benefits." Control Systems Technology Journal, vol. 31, no. 4, 2022, pp. 445-462.

5. Parker, J.N., and Singh, R.V. "Wireless Monitoring Solutions for Remote Valve Applications in Petrochemical Industries." Process Safety and Environmental Protection, vol. 167, 2023, pp. 78-92.

6. Taylor, M.E., Johnson, C.L., and White, S.A. "Performance Optimization of Pneumatic Bellows Control Valves Through Advanced Actuator Integration." Flow Control and Instrumentation Magazine, vol. 42, no. 8, 2023, pp. 112-128.

_1745994738000.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI