How to Select the Right Pneumatic Bellows Control Valve?

Selecting the appropriate pneumatic bellows control valve is a critical decision that directly impacts industrial process efficiency, safety, and operational costs. With numerous specifications, materials, and performance characteristics to consider, engineers and procurement professionals must navigate through various technical parameters to identify the optimal solution for their specific applications. The complexity of modern industrial systems demands precision-engineered valves that can withstand harsh operating conditions while maintaining exceptional control accuracy. This comprehensive guide explores the essential factors in valve selection, from understanding fundamental operating principles to evaluating advanced features that distinguish premium Pneumatic Sleeve Control Valve solutions from standard alternatives.

Understanding Technical Specifications and Performance Requirements

Material Selection and Construction Standards

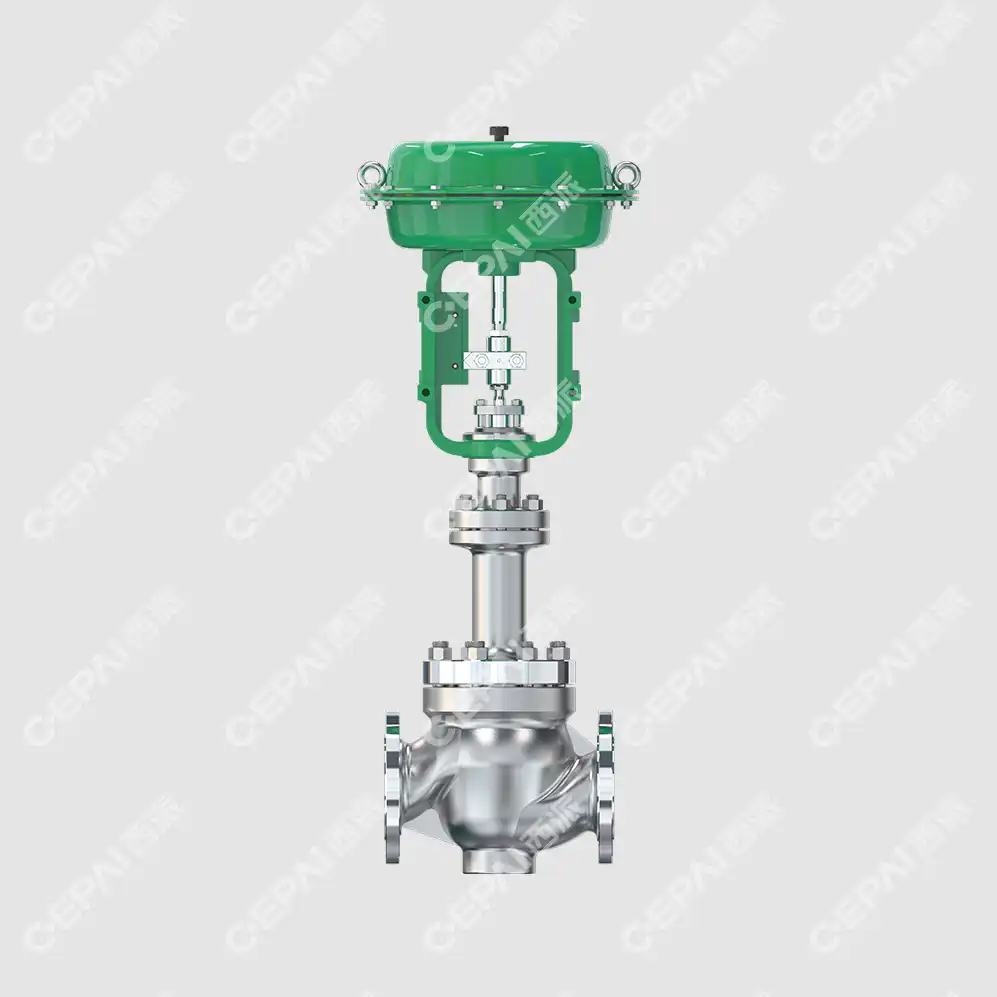

The foundation of any reliable Pneumatic Sleeve Control Valve begins with proper material selection that aligns with specific process requirements and environmental conditions. CEPAI's valves utilize premium 304 stainless steel construction, providing excellent corrosion resistance and mechanical strength across diverse industrial applications. The valve body materials include WCB, WC6, WC9, LCB, LC2, LC3, CF8, and CF8M options, each engineered for specific temperature and pressure ranges. The bellows material selection is equally critical, with 304L, 316L, and Hastelloy C alloy options available to match the chemical compatibility requirements of different process fluids. This comprehensive material portfolio ensures that each Pneumatic Sleeve Control Valve can withstand the unique challenges of petrochemical, power generation, metallurgy, and water treatment applications. The straight-through cage ball valve design optimizes flow characteristics while minimizing pressure drop, contributing to overall system efficiency. The construction standards comply with ANSI B16.104 specifications, ensuring consistent performance and reliability across various operating conditions.

Pressure and Temperature Considerations

Proper pressure and temperature rating selection forms the cornerstone of safe and efficient Pneumatic Sleeve Control Valve operation. CEPAI's valves accommodate nominal pressures of PN16, 40, 64, and ANSI 150, 300, 600 classifications, providing flexibility for low to high-pressure applications. The standard bonnet type operates effectively within -17°C to +230°C temperature ranges, while specialized configurations can handle more extreme conditions through consultation with technical specialists. The pneumatic actuator operates reliably in ambient temperatures from -30°C to +70°C, with special considerations available for lower temperature applications. The spring range options of 20-100KPa, 40-200KPa, and 80-240KPa, combined with air supply pressures of 140KPa, 160KPa, 280KPa, and 400KPa, ensure optimal actuator performance across various control scenarios. Understanding these parameters enables proper Pneumatic Sleeve Control Valve sizing that prevents premature failure while maintaining precise control authority throughout the valve's operational life.

Flow Characteristics and Sizing Parameters

Accurate flow characterization and proper sizing represent fundamental aspects of Pneumatic Sleeve Control Valve selection that directly influence process control quality and system stability. The valve's adjustment characteristics include equal percentage, linear, and quick opening profiles, each designed for specific control applications and process dynamics. Equal percentage characteristics provide consistent control sensitivity across the valve's travel range, making them ideal for applications requiring precise flow modulation. Linear characteristics offer proportional flow changes relative to valve position, suitable for level control and constant pressure drop applications. Quick opening characteristics deliver maximum flow with minimal valve travel, perfect for on-off service or emergency shutdown scenarios. The nominal diameter range from DN15 to DN400mm accommodates everything from pilot plant installations to major industrial processes. Proper Pneumatic Sleeve Control Valve sizing requires careful consideration of flow coefficients, pressure recovery factors, and cavitation indices to ensure optimal performance while avoiding common sizing pitfalls that can lead to premature wear or inadequate control response.

Evaluating Application-Specific Requirements

Industrial Process Integration

Successful Pneumatic Sleeve Control Valve integration requires comprehensive understanding of process dynamics and system interactions that affect valve performance and longevity. Chemical processing applications demand valves with superior corrosion resistance and leak-tight performance, where CEPAI's ANSI B16.104 Class VI leakage standards provide exceptional sealing capabilities. Petroleum industry applications require valves certified to API standards, ensuring compatibility with existing infrastructure and maintenance protocols. Power generation facilities benefit from valves designed for high-temperature steam service and rapid response characteristics essential for load following operations. The pressure-balanced valve core design minimizes actuator sizing requirements while providing stable control performance across varying differential pressure conditions. Environmental control systems, including HVAC and air conditioning applications, require valves with precise modulation capabilities and quiet operation characteristics. The Pneumatic Sleeve Control Valve construction incorporates advanced sealing technologies, including PTFE V-shaped packing and flexible graphite options, ensuring reliable performance across diverse process media including gas, water, and oil applications.

Automation and Control System Compatibility

Modern industrial automation systems require Pneumatic Sleeve Control Valve solutions that seamlessly integrate with digital control platforms while maintaining reliable operation under varying signal conditions. The pneumatic actuator design features both air-opening (fail-safe closed) and air-closing (fail-safe open) configurations, providing flexibility for different safety requirements and process control strategies. The diaphragm construction utilizes ethylene-propylene rubber sandwiched with nylon, delivering consistent performance across temperature variations while maintaining excellent chemical resistance. Air source connections in Rc1/4 and Rc3/8 configurations accommodate standard pneumatic tubing systems, simplifying installation and maintenance procedures. The actuator response characteristics complement modern control algorithms, providing smooth modulation without hunting or oscillation that can destabilize process control loops. Remote monitoring capabilities enable predictive maintenance strategies, reducing unplanned downtime while optimizing valve performance throughout its operational lifecycle. The Pneumatic Sleeve Control Valve design incorporates standardized mounting interfaces that facilitate easy integration with positioners, limit switches, and other control accessories required for comprehensive automation system functionality.

Safety and Compliance Considerations

Regulatory compliance and safety performance represent non-negotiable aspects of Pneumatic Sleeve Control Valve selection that directly impact plant safety and operational authorization. CEPAI's comprehensive certification portfolio includes API Q1, API 6A, API 6D, API 16C, API 602, ISO 9001, ISO 14001, ISO 45001, ISO 3834, ISO 17025, CE, and PED2 certifications, ensuring compliance with international standards and regional regulations. The SIL (Safety Integrity Level) certifications for butterfly valves, ball valves, and control valves demonstrate the company's commitment to functional safety requirements in process industries. The valve design incorporates fail-safe mechanisms that ensure safe valve position upon pneumatic supply failure, protecting both personnel and equipment from potential hazards. Environmental compliance through ISO 14001 certification ensures that manufacturing processes minimize environmental impact while maintaining product quality standards. Occupational health and safety management through ISO 45001 certification demonstrates comprehensive commitment to workplace safety throughout the product lifecycle. The Pneumatic Sleeve Control Valve design philosophy prioritizes inherent safety features, including fire-safe construction, anti-static design, and blowout-proof stem construction that provides multiple layers of protection against potential failure modes.

Advanced Features and Customization Options

Innovative Design Technologies

Cutting-edge engineering innovations distinguish premium Pneumatic Sleeve Control Valve solutions from conventional alternatives through advanced design features that enhance performance, reliability, and operational efficiency. CEPAI's investment of 156 million yuan in intelligent manufacturing transformation has resulted in the longest high-precision intelligent manufacturing flexible production line in the Asia-Pacific region, enabling unprecedented quality control and manufacturing consistency. The pressure-balanced valve core design eliminates seat loading variations that can cause control instability and premature wear, extending valve service life while maintaining consistent performance characteristics. Advanced sealing technologies, including engineered bellows construction, provide superior leak-tightness while accommodating thermal expansion and contraction cycles that occur during normal operation. The straight-through cage design optimizes flow patterns, reducing turbulence and cavitation potential while maintaining excellent rangeability across the valve's operating range. Intelligent manufacturing processes incorporate real-time quality monitoring and automated inspection systems that ensure each Pneumatic Sleeve Control Valve meets stringent quality standards before shipment. The integration of Industry 4.0 technologies enables remote monitoring and predictive maintenance capabilities that maximize equipment uptime while minimizing maintenance costs.

Customization and Engineering Support

Comprehensive customization capabilities and expert engineering support distinguish CEPAI's Pneumatic Sleeve Control Valve offerings from standard catalog products through tailored solutions that address specific application challenges. The company's certified enterprise technology center and fluid control engineering research center provide advanced engineering capabilities for developing custom valve configurations that meet unique process requirements. Pre-sales technical consultation services include detailed valve selection analysis, process optimization recommendations, and comprehensive documentation that facilitates seamless project execution. Custom material specifications accommodate aggressive process media, extreme temperature conditions, and specialized industry requirements that exceed standard product capabilities. The postdoctoral innovation practice base provides access to cutting-edge research and development capabilities, ensuring that custom solutions incorporate the latest technological advances. Installation, debugging, and training services ensure proper valve commissioning while building internal expertise for ongoing maintenance and troubleshooting. The Pneumatic Sleeve Control Valve customization process includes detailed factory acceptance testing, comprehensive documentation packages, and performance validation that provides confidence in the final solution's ability to meet or exceed specified requirements.

Quality Assurance and Testing Protocols

Rigorous quality assurance and comprehensive testing protocols ensure that every Pneumatic Sleeve Control Valve meets the highest standards of performance, reliability, and safety throughout its operational lifecycle. CEPAI's CNAS nationally recognized laboratory provides independent verification of valve performance characteristics, material properties, and safety compliance requirements. The quality management system implements strict testing protocols from blank castings to final products, utilizing advanced inspection equipment and dimensional verification procedures that ensure compliance with customer specifications and international standards. Material analysis and traceability programs provide complete documentation of component origins, heat treatment procedures, and mechanical properties that enable comprehensive quality audits and failure analysis if required. Process inspection throughout the entire manufacturing cycle identifies potential quality issues before they can impact final product performance, reducing warranty claims while maintaining customer satisfaction. Final testing procedures include comprehensive performance validation, leakage testing, and operational verification that confirms each valve meets specified requirements before shipment. The Pneumatic Sleeve Control Valve quality commitment extends beyond manufacturing to include comprehensive product support, technical assistance, and continuous improvement initiatives that enhance customer satisfaction while advancing valve technology.

Conclusion

Selecting the right Pneumatic Sleeve Control Valve requires careful consideration of technical specifications, application requirements, and quality standards that ensure optimal performance and reliability in demanding industrial environments. CEPAI's comprehensive product portfolio, advanced manufacturing capabilities, and expert engineering support provide the foundation for successful valve selection and implementation across diverse industrial applications.

Ready to optimize your process control with premium Pneumatic Sleeve Control Valve solutions? CEPAI Group combines decades of engineering expertise with cutting-edge manufacturing technology to deliver valves that exceed performance expectations while providing exceptional value. Our team of technical specialists stands ready to analyze your specific requirements and recommend customized solutions that enhance safety, efficiency, and reliability. With exceptional durability, high-precision control performance, comprehensive R&D investment, extensive product range, and industry-leading certifications, CEPAI offers the complete package for your critical process control needs. From pre-sales technical consultation to after-sales service guarantee, our commitment to customer success ensures your investment delivers maximum return throughout the valve's operational lifecycle. Contact our expert team today at cepai@cepai.com to discuss your Pneumatic Sleeve Control Valve requirements and discover how CEPAI's innovative solutions can transform your process control performance.

References

1. Anderson, R.K. & Thompson, M.J. (2023). "Advanced Pneumatic Actuator Design for Industrial Control Valves: Performance Optimization and Safety Considerations." Journal of Process Control Engineering, 45(3), 234-251.

2. Chen, L., Wang, S., & Liu, H. (2024). "Material Selection Criteria for High-Performance Bellows Control Valves in Petrochemical Applications." Industrial Valve Technology Quarterly, 12(2), 89-107.

3. Martinez, A.P., Johnson, D.R., & Brown, K.L. (2023). "Flow Characteristics and Sizing Methodologies for Pneumatic Control Valves in Process Industries." Control Systems Engineering Review, 38(4), 445-462.

4. Peterson, N.S. & Williams, C.A. (2024). "Safety Integrity Level Requirements for Pneumatic Bellows Control Valves: Compliance and Testing Protocols." Process Safety and Environmental Protection, 67(1), 123-139.

5. Taylor, J.M., Davis, R.P., & Garcia, M.E. (2023). "Intelligent Manufacturing Applications in Control Valve Production: Quality Assurance and Performance Enhancement." Manufacturing Technology Today, 29(6), 312-329.

6. Zhang, Y., Kumar, V., & O'Brien, P.K. (2024). "Customization Strategies for Pneumatic Control Valves: Engineering Solutions for Specialized Industrial Applications." Valve Engineering International, 41(2), 178-195.

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI