Common Mistakes to Avoid When Installing a High-Temperature Valve

Installing a High-Temperature Control Valve can be a critical operation that determines the success or failure of your entire industrial system. Imagine discovering that your valve installation has compromised your production line's safety and efficiency after months of operation. This comprehensive guide reveals the most common installation mistakes that could cost you thousands in repairs and downtime, while providing professional insights to ensure your High-Temperature Control Valve performs flawlessly for years to come.

Critical Material Selection Errors for High-Temperature Control Valve Applications

One of the most devastating mistakes in high-temperature valve installation involves selecting inappropriate materials that cannot withstand extreme thermal conditions. When installing a High-Temperature Control Valve, engineers often underestimate the thermal expansion and contraction effects on valve components. The valve body material selection becomes crucial as different metals expand at varying rates when exposed to temperatures ranging from 200°C to 600°C or higher. Professional installers must understand that standard carbon steel materials may experience significant dimensional changes under extreme heat, leading to binding, leakage, or complete valve failure. For High-Temperature Control Valve applications, materials such as stainless steel grades 304, 316, or specialized alloys like Inconel and Hastelloy provide superior thermal resistance. These materials maintain their structural integrity and dimensional stability even when subjected to rapid temperature fluctuations that are common in petrochemical and power generation applications. The selection process must also consider the flow medium characteristics. For instance, when handling corrosive gases or steam at high temperatures, the High-Temperature Control Valve requires materials that resist both thermal stress and chemical attack. Failure to properly match material properties with operational conditions results in premature wear, increased maintenance costs, and potential safety hazards that could have been easily avoided with proper initial planning.

-

Thermal Expansion Compensation Planning

Inadequate thermal expansion compensation represents another critical oversight in High-Temperature Control Valve installation. During operation, valve components experience significant dimensional changes that must be accommodated through proper piping design and support systems. Engineers frequently fail to calculate the actual thermal expansion coefficients for their specific installation conditions, leading to excessive stress on valve connections and associated piping systems. The compensation system must include expansion joints, flexible connections, or specially designed piping arrangements that allow for thermal movement without imposing harmful loads on the High-Temperature Control Valve. Additionally, support structures must be positioned to guide thermal expansion in predetermined directions while preventing binding or misalignment of valve components. This planning phase requires detailed thermal analysis and stress calculations to ensure long-term operational reliability.

-

Incorrect Insulation and Heat Management Strategies

Poor insulation practices around High-Temperature Control Valve installations create numerous operational problems that extend far beyond energy efficiency concerns. Insufficient insulation allows excessive heat transfer to surrounding equipment and structures, potentially creating safety hazards for maintenance personnel and affecting the performance of nearby sensitive components. Conversely, over-insulation can trap heat within the valve assembly, leading to overheating of actuator components and control systems that were not designed for extreme thermal exposure. The insulation system design must provide adequate thermal protection while maintaining accessibility for routine maintenance and inspection activities. Removable insulation panels and access ports should be strategically positioned to allow temperature monitoring and valve adjustments without compromising the overall thermal management system. Furthermore, the insulation material selection must consider chemical compatibility with potential leakage from the High-Temperature Control Valve and surrounding process equipment.

Installation Environment and Positioning Mistakes

Environmental considerations play a crucial role in High-Temperature Control Valve installation success, yet many projects overlook critical positioning and environmental factors that directly impact valve performance and longevity. The installation location must provide adequate space for thermal expansion, maintenance access, and proper drainage of condensate or process fluids that may accumulate during operation. Positioning the High-Temperature Control Valve too close to heat sources such as furnaces, boilers, or other high-temperature equipment can create localized overheating that exceeds the valve's design specifications. Even with proper insulation, radiant heat from nearby equipment can affect actuator performance and control system accuracy. The installation design should include heat shields or sufficient spacing to protect the valve from external thermal influences that could compromise its operational reliability. Inadequate consideration of wind patterns, precipitation exposure, and ambient temperature variations in outdoor installations frequently leads to operational problems. High-Temperature Control Valves installed in exposed locations require weather protection systems that prevent thermal shocking from rapid temperature changes while maintaining proper ventilation for heat dissipation. The protection system must also prevent moisture accumulation that could cause corrosion or interfere with actuator operation.

-

Improper Foundation and Support Design

Foundation inadequacies represent a frequently overlooked aspect of High-Temperature Control Valve installation that can lead to catastrophic operational failures. The foundation system must accommodate not only the static weight of the valve and associated piping but also the dynamic loads created by thermal expansion and contraction cycles. Insufficient foundation design results in valve misalignment, binding, and premature wear of sealing components. The support structure design must distribute loads evenly while allowing for controlled thermal movement. This requires careful calculation of thermal forces and proper anchoring strategies that guide expansion in predetermined directions. Additionally, the foundation must provide stable support for actuator mounting and control system components that require precise alignment for optimal performance. Vibration isolation may also be necessary in installations where the High-Temperature Control Valve is subject to external mechanical disturbances.

-

Electrical and Control System Integration Errors

Electrical system integration for High-Temperature Control Valve installations presents unique challenges that are frequently misunderstood during the installation process. High-temperature environments can affect electrical components and wiring systems in ways that compromise control accuracy and reliability. Standard electrical components may experience drift, failure, or reduced lifespan when exposed to elevated temperatures, even when not in direct contact with the hot process medium. The control system design must account for temperature effects on sensor accuracy, signal transmission, and actuator performance. Temperature compensation algorithms may be necessary to maintain control precision throughout the operational temperature range. Additionally, electrical conduit and wiring must be rated for the expected ambient temperatures and protected from thermal cycling that could cause fatigue failures. Proper grounding and electrical isolation become critical in high-temperature applications where thermal expansion can affect electrical connections and create safety hazards.

Actuator Selection and Configuration Problems

Actuator selection for High-Temperature Control Valve applications requires careful consideration of thermal effects on mechanical and electrical components. Many installation failures stem from selecting standard actuators that cannot maintain proper operation when exposed to elevated ambient temperatures or radiant heat from the process system. The actuator must provide consistent torque output and positioning accuracy throughout the expected temperature range while maintaining safe operation for maintenance personnel. Electric actuators used with High-Temperature Control Valve systems require special attention to motor cooling and electronic component protection. Standard motors may experience reduced efficiency and shortened lifespan when operating in high-temperature environments. Additionally, electronic control circuits require thermal protection and may need active cooling systems to maintain proper operation. The actuator housing design should provide thermal isolation between hot valve components and temperature-sensitive control electronics. Pneumatic actuators present different challenges in high-temperature applications, particularly regarding air supply quality and temperature effects on sealing components. High temperatures can cause pneumatic seals to harden and lose flexibility, leading to increased leakage and reduced actuator performance. The air supply system must include proper filtration and temperature conditioning to ensure consistent actuator operation. Additionally, pneumatic supply lines must be insulated and supported to prevent thermal expansion from affecting actuator alignment.

-

Control Signal and Feedback System Issues

Control signal integrity becomes critically important in High-Temperature Control Valve installations where thermal effects can introduce errors and instability in the control loop. Temperature variations can affect signal transmission characteristics and introduce drift in feedback sensors that compromise control accuracy. The control system design must include temperature compensation strategies and signal conditioning to maintain stable operation throughout the thermal operating range. Position feedback systems require special consideration in high-temperature applications where thermal expansion can affect mechanical linkages and sensor positioning. Feedback sensors must be selected for their thermal stability and protected from direct exposure to high temperatures that could cause calibration drift or component failure. Additionally, the mounting system for feedback devices must accommodate thermal expansion without affecting measurement accuracy or introducing mechanical stress that could lead to component failure.

Sealing and Leakage Prevention Challenges

Sealing system design represents one of the most critical aspects of High-Temperature Control Valve installation, as thermal cycling creates unique challenges for maintaining leak-tight operation over extended periods. Standard sealing materials may not provide adequate performance when subjected to high temperatures and thermal cycling that causes dimensional changes in valve components. The sealing system must accommodate thermal expansion while maintaining effective sealing throughout the operational temperature range. Packing systems for High-Temperature Control Valve applications require special materials and design considerations that differ significantly from standard temperature applications. Graphite-based packing materials often provide superior performance in high-temperature applications, but proper installation techniques are critical to ensure effective sealing. The packing box design must provide adequate compression while allowing for thermal expansion of the valve stem and packing materials. Gasket selection and installation practices become particularly important in flanged connections associated with High-Temperature Control Valve systems. Metallic gaskets may be required for extreme temperature applications, but proper installation requires specialized techniques and torque procedures that differ from standard gasket applications. Additionally, flange face preparation becomes critical to ensure proper gasket seating and prevent leakage under thermal cycling conditions.

-

Valve Stem and Actuator Connection Integrity

The connection between the High-Temperature Control Valve stem and actuator presents unique challenges that require careful attention during installation. Thermal expansion of valve components can affect the alignment and coupling between the valve stem and actuator drive, potentially leading to binding, excessive wear, or complete failure of the connection system. The coupling design must accommodate thermal movement while transmitting actuator torque effectively throughout the operational temperature range. Stem packing systems require regular adjustment and maintenance in high-temperature applications due to thermal cycling effects on packing materials and valve stem dimensions. The packing adjustment procedure must be performed while the valve is at operating temperature to ensure proper compression and sealing effectiveness. Inadequate packing adjustment can result in excessive leakage or binding that compromises valve performance and creates safety hazards.

Conclusion

Proper installation of High-Temperature Control Valve systems requires comprehensive understanding of thermal effects, material properties, and environmental considerations that extend far beyond standard valve installation practices. The most critical mistakes involve material selection, thermal expansion compensation, environmental protection, and sealing system design that must be addressed during the initial planning phase to ensure long-term operational success.

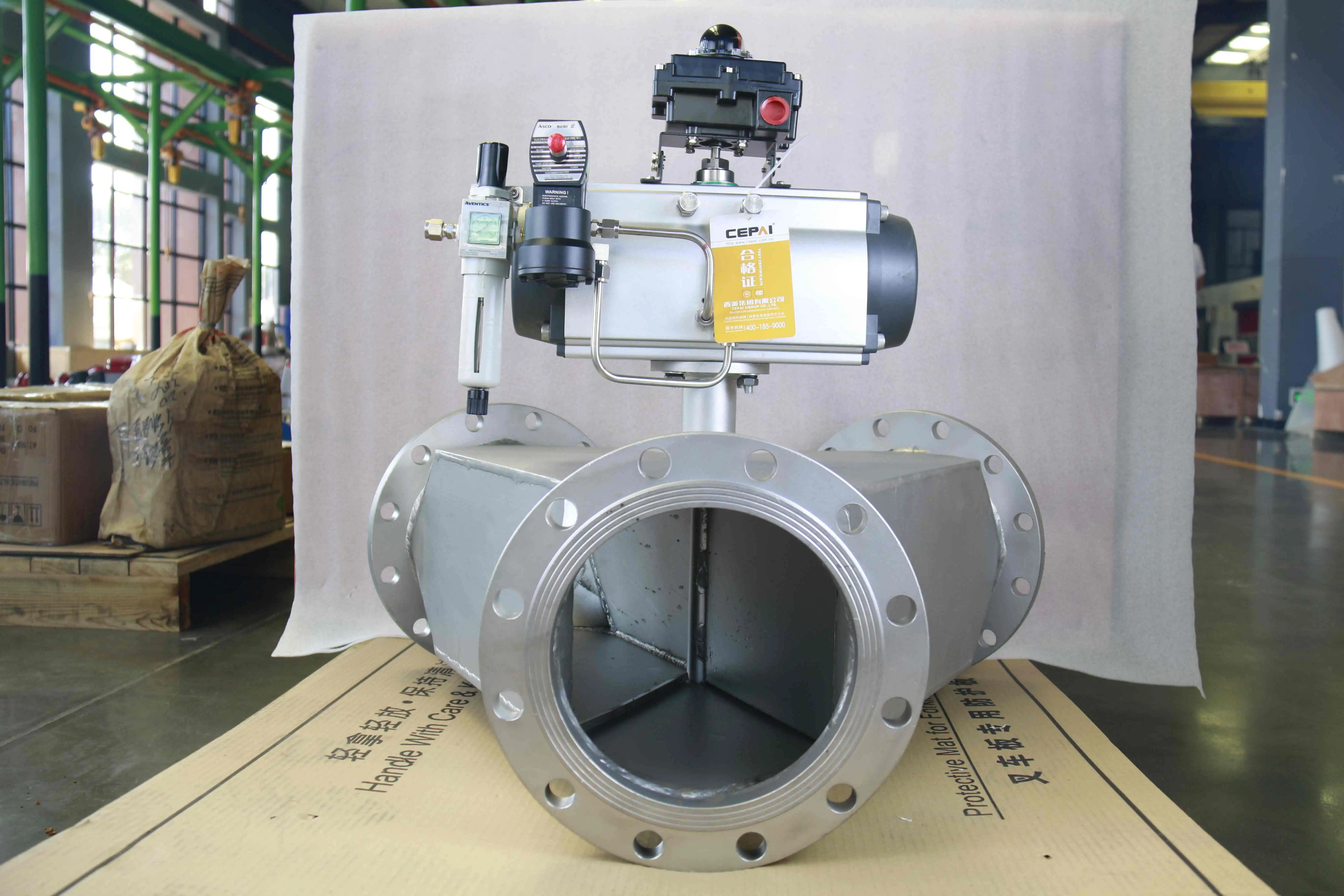

Cooperate with CEPAI Group Co., LTD.

CEPAI Group Co., LTD. stands as China's leading High-Temperature Control Valve manufacturer and supplier, bringing over 15 years of specialized expertise to demanding industrial applications worldwide. As a nationally recognized high-tech enterprise and Jiangsu Province intelligent manufacturing demonstration factory, CEPAI has invested 156 million yuan in advanced production capabilities, establishing the Asia Pacific region's longest high-precision intelligent manufacturing flexible production line.

Our comprehensive product line includes electric low-temperature regulating valves with operating ranges from -60°C to -20°C, featuring AC power supply compatibility (220V/380V), 4-20mA control signals, and precision opening ranges of 0-90 degrees or 0-180 degrees. As a certified China High-Temperature Control Valve factory and China High-Temperature Control Valve supplier, we maintain strict quality standards through ISO 9001, ISO 14001, and ISO 45001 certifications, ensuring exceptional durability and high-precision control performance.

CEPAI's intelligent manufacturing capabilities include remote AR operation and maintenance guidance, comprehensive pre-sales technical consultation, customized solution services, and guaranteed after-sales support. Our products serve major clients including PetroChina, Sinopec, CNOOC, China Datang Group, and Baowu Group. Whether you need China High-Temperature Control Valve wholesale solutions or High-Temperature Control Valve for sale, our High Quality High-Temperature Control Valve products deliver superior performance at competitive High-Temperature Control Valve price points. Contact our technical team at cepai@cepai.com for expert consultation and customized solutions that ensure your critical applications operate safely and efficiently.

FAQ

Q: What temperature range can CEPAI's High-Temperature Control Valves handle?

A: CEPAI's valves operate effectively in extreme conditions, with specialized models handling temperatures from -196°C to +600°C depending on application requirements and material specifications.

Q: How do I prevent thermal expansion issues during High-Temperature Control Valve installation?

A: Use proper expansion joints, calculate thermal coefficients accurately, design flexible piping supports, and ensure adequate clearance for thermal movement throughout the system.

Q: What materials should I select for high-temperature valve applications?

A: Choose stainless steel grades 304/316, specialized alloys like Inconel, or carbon steel with appropriate coatings based on temperature range and process medium characteristics.

Q: How often should High-Temperature Control Valve packing be adjusted?

A: Adjust packing systems at operating temperature during initial commissioning and subsequently every 3-6 months or based on leakage monitoring and manufacturer recommendations.

References

1. "High Temperature Valve Design and Installation Guidelines" - American Society of Mechanical Engineers (ASME), Industrial Valve Standards Committee

2. "Thermal Effects on Industrial Control Valve Performance" - Dr. Sarah Chen, Journal of Process Control Engineering, Mechanical Engineering Research Institute

3. "Best Practices for High-Temperature Piping Systems Installation" - International Association of Plumbing and Mechanical Officials, Technical Standards Division

4. "Material Selection for Extreme Temperature Valve Applications" - Prof. Michael Rodriguez, Industrial Materials Engineering Handbook, Third Edition

_1745994800896.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI