What Makes a Sleeve Control Valve the Go-To for Noise Reduction?

Industrial facilities worldwide face a critical challenge that can shut down operations, violate safety regulations, and create hostile working environments: excessive valve noise. When control valves generate sound levels exceeding 85 dBA, workers suffer hearing damage, communities file complaints, and regulatory bodies impose costly penalties. The Sleeve Control Valve emerges as the engineered solution that transforms these noisy industrial nightmares into quiet, efficient operations. This innovative valve design addresses the root causes of acoustic emissions while maintaining precise flow control, making it the preferred choice for noise-sensitive applications across petrochemical, power generation, and process industries.

The Science Behind Sleeve Control Valve Noise Reduction Technology

-

Understanding Acoustic Engineering in Valve Design

The fundamental principle that makes a Sleeve Control Valve superior for noise reduction lies in its unique flow path geometry and pressure recovery characteristics. Sleeve control valves excel in larger systems requiring higher pressure differentials, providing enhanced stability, noise reduction, and clog resistance. Unlike conventional globe valves that create turbulent flow patterns through sudden direction changes, the Sleeve Control Valve employs a cylindrical sleeve with precisely machined ports that guide fluid flow in a more controlled manner. This design philosophy minimizes the velocity fluctuations and pressure pulsations that generate acoustic energy. The sleeve mechanism functions as an acoustic dampener by distributing pressure drops across multiple stages rather than creating a single high-velocity jet. When fluid passes through the sleeve ports, it undergoes gradual expansion and pressure recovery, significantly reducing the formation of cavitation bubbles and turbulent eddies that are primary noise sources. Advanced computational fluid dynamics studies demonstrate that properly designed sleeve configurations can achieve noise reductions of 10-15 dBA compared to traditional valve designs, bringing industrial installations into compliance with occupational health standards.

-

Multi-Stage Pressure Reduction Principles

The Sleeve Control Valve incorporates multi-stage pressure reduction technology that fundamentally changes how energy dissipation occurs within the valve body. Each port in the sleeve acts as an individual throttling element, creating a series of smaller pressure drops instead of one large pressure differential. This staged approach prevents the formation of high-velocity jets that would otherwise generate significant acoustic emissions. The fluid velocity remains below critical thresholds throughout the flow path, minimizing turbulence-induced noise generation. Furthermore, the sleeve geometry allows for optimized flow coefficient (Cv) values while maintaining low noise characteristics. The relationship between flow capacity and noise generation becomes decoupled, enabling engineers to specify valves that meet both performance and acoustic requirements simultaneously. This design advantage makes the Sleeve Control Valve particularly valuable in applications where traditional noise reduction methods like diffusers or silencers would be impractical or insufficient.

Advanced Trim Designs for Maximum Acoustic Performance

-

Specialized Port Configurations and Flow Patterns

Modern Sleeve Control Valve designs incorporate sophisticated trim configurations specifically engineered for acoustic optimization. The port arrangement follows principles derived from aerodynamic and hydrodynamic noise research, utilizing patterns that minimize jet impingement and pressure wave formation. Staggered port configurations prevent acoustic resonance by eliminating periodic flow disturbances that could amplify noise generation. The spacing, diameter, and angular orientation of each port are calculated using proprietary algorithms that consider fluid properties, operating conditions, and acoustic targets. The most advanced trim designs feature variable port geometries that adapt to different flow conditions. At low flow rates, smaller ports maintain velocity control and prevent whistling phenomena. As flow increases, larger ports become active, maintaining optimal velocity profiles throughout the operating range. This adaptive characteristic ensures consistent noise performance across the valve's full operational spectrum, addressing the common problem of valves that perform well at design conditions but generate excessive noise during turndown operations.

-

Material Engineering for Sound Absorption

The construction materials and surface treatments of Sleeve Control Valve components play crucial roles in noise mitigation. High-performance alloys with specific metallurgical properties provide both mechanical strength and acoustic dampening characteristics. Surface texturing techniques create microscopic patterns that disrupt boundary layer formation and reduce turbulence intensity. These engineered surfaces function as passive noise control systems, continuously attenuating acoustic energy without requiring external power or maintenance. Advanced coating technologies further enhance the acoustic performance of sleeve components. Specialized ceramic and polymer coatings not only provide corrosion resistance but also modify the acoustic impedance of metal surfaces, reducing sound transmission through valve bodies. The combination of optimized base materials and acoustic coatings can achieve additional noise reductions of 3-5 dBA beyond what geometric design alone provides, making the Sleeve Control Valve the definitive solution for the most demanding noise control applications.

Industrial Applications and Performance Advantages

-

Critical Noise-Sensitive Installations

The Sleeve Control Valve has become indispensable in industrial applications where noise control directly impacts operational viability and regulatory compliance. Understanding and reducing noise from control valves is an important consideration for the process industries, especially those close to residential areas. Petroleum refineries operating near residential communities rely on these valves to maintain processing capacity while meeting increasingly stringent noise ordinances. The valve's ability to handle high-pressure steam and hydrocarbon services while maintaining acoustic compliance makes it essential for modern refinery operations. Power generation facilities represent another critical application area where Sleeve Control Valve technology provides substantial operational benefits. Steam turbine bypass systems, feedwater control applications, and condensate throttling services all benefit from the reduced acoustic emissions and improved flow stability that sleeve designs provide. The enhanced controllability characteristics of these valves also contribute to improved plant efficiency and reduced maintenance requirements, creating economic advantages that extend far beyond noise reduction benefits.

-

Comparison with Traditional Valve Technologies

When compared to conventional control valve designs, the Sleeve Control Valve demonstrates superior performance across multiple operational parameters. Traditional globe valves with single-stage pressure reduction typically generate 15-20 dBA higher noise levels under equivalent operating conditions. The acoustic advantages become even more pronounced in high-pressure drop applications where conventional valves would require external silencing equipment. The integrated noise control provided by sleeve design eliminates the need for bulky and expensive downstream silencers, reducing installation costs and space requirements. The operational reliability of Sleeve Control Valve technology also surpasses traditional alternatives in demanding service conditions. The guided flow path reduces erosion and cavitation damage, extending service life and reducing maintenance interventions. This enhanced durability is particularly valuable in applications where valve accessibility is limited or where unscheduled shutdowns carry significant economic penalties. The combination of acoustic performance and operational reliability makes the Sleeve Control Valve the preferred choice for critical industrial applications worldwide.

Engineering Specifications and Selection Criteria

-

Technical Parameters for Optimal Performance

Proper selection and sizing of Sleeve Control Valve systems requires careful consideration of multiple engineering parameters that influence both flow control and acoustic performance. The noise prediction calculations must account for fluid properties, pressure conditions, temperature effects, and downstream piping configurations. Advanced sizing software incorporates acoustic modeling algorithms that predict noise levels with accuracy typically within 2-3 dBA of measured values, enabling engineers to specify valve configurations that meet project requirements with confidence. The relationship between valve capacity and noise generation follows well-established engineering principles, but the implementation in sleeve valve designs requires specialized expertise. The effective flow coefficient (Cv) must be balanced against acoustic targets, with consideration given to turndown requirements and control stability. Modern Sleeve Control Valve designs achieve this optimization through sophisticated trim geometries that maintain linear installed characteristics while minimizing noise generation across the full operating range.

-

Installation and Commissioning Best Practices

Successful implementation of Sleeve Control Valve technology requires adherence to proven installation and commissioning procedures that maximize acoustic performance. Proper upstream and downstream piping configurations are essential for achieving predicted noise levels and maintaining flow stability. The installation guidelines specify minimum straight pipe lengths, support requirements, and isolation procedures that prevent acoustic coupling with adjacent piping systems. Commissioning procedures for noise-critical applications include comprehensive acoustic testing protocols that verify performance against project specifications. Sound level measurements at multiple locations around the valve installation provide data for correlation with predictive models and validation of acoustic performance. These measured results form the baseline for ongoing condition monitoring programs that track valve performance throughout its operational life, enabling predictive maintenance strategies that maintain optimal acoustic characteristics.

CEPAI Group's Advanced Manufacturing Excellence

-

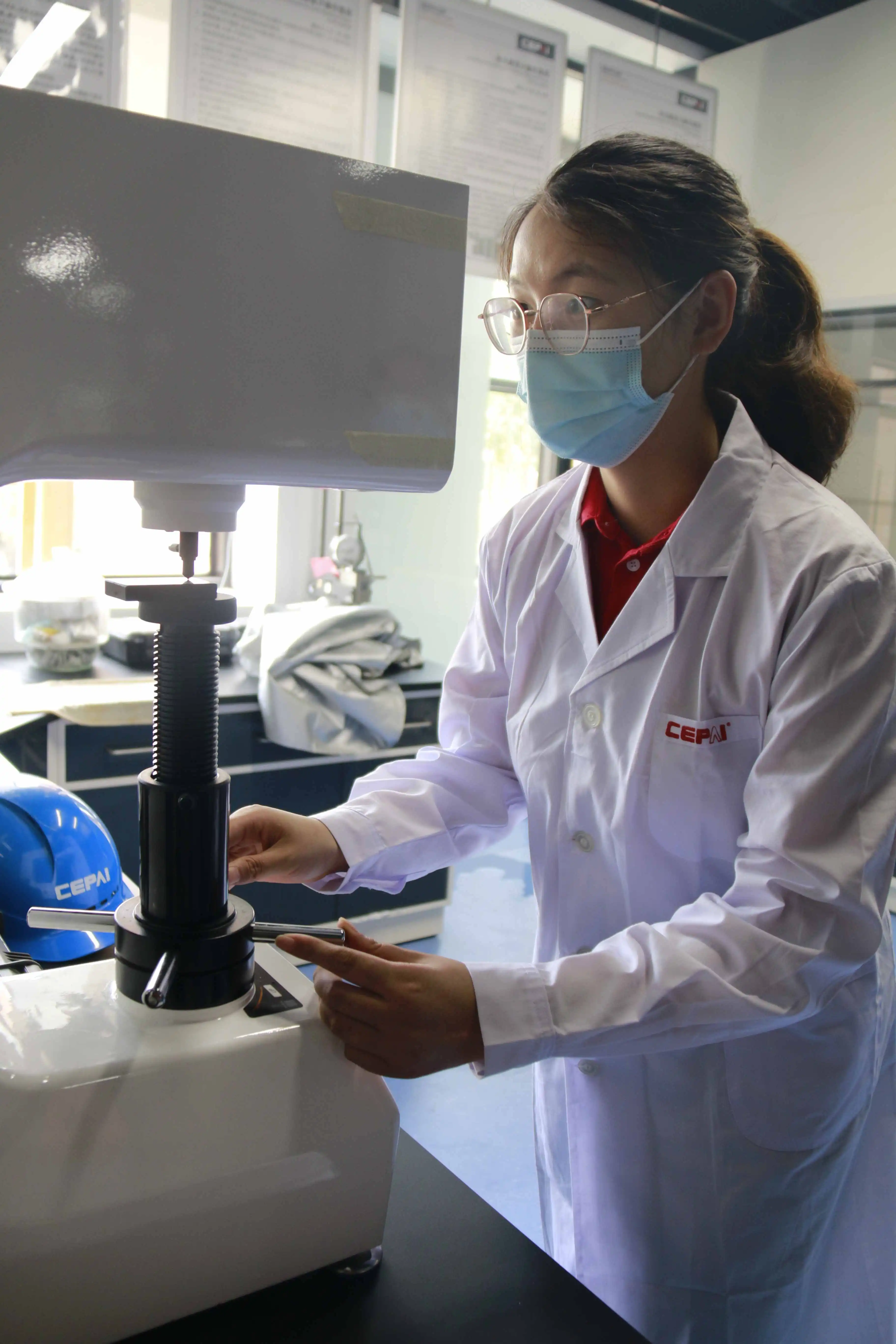

Precision Manufacturing and Quality Control

CEPAI Group Co., Ltd. has established itself as a leading manufacturer of high-performance Sleeve Control Valve systems through implementation of advanced manufacturing technologies and rigorous quality control processes. The company's 156 million yuan investment in intelligent manufacturing infrastructure has created the longest high-precision flexible production line in the Asia Pacific region, enabling production of sleeve valve components with tolerances that directly impact acoustic performance. This manufacturing precision ensures consistent valve-to-valve performance and predictable noise characteristics across production batches. The company's comprehensive quality management system, certified to ISO 9001 standards, implements strict testing protocols that verify acoustic performance during the manufacturing process. Each Sleeve Control Valve undergoes acoustic testing using calibrated sound measurement equipment before shipment, ensuring that delivered products meet specified noise limits. This quality assurance approach eliminates the uncertainty and field modifications that often accompany valve installations in noise-sensitive applications, providing customers with confidence in their acoustic compliance.

-

Research and Development Innovation

CEPAI Group's commitment to continuous innovation in Sleeve Control Valve technology is demonstrated through its extensive research and development infrastructure. The company operates multiple certified technology centers including the Jiangsu Provincial Fluid Control Engineering Technology Research Center and High-Performance Fluid Control Device Engineering Research Center. These facilities conduct advanced research in acoustic engineering, computational fluid dynamics, and materials science that directly supports the development of next-generation noise control solutions. The company's research programs collaborate with leading academic institutions and industry partners to advance the fundamental understanding of valve acoustics and noise generation mechanisms. This collaborative approach has resulted in numerous patents and technological breakthroughs that maintain CEPAI's position at the forefront of acoustic control valve technology. The continuous investment in research and development ensures that CEPAI's Sleeve Control Valve products incorporate the latest scientific advances and maintain competitive advantages in performance and reliability.

Conclusion

The Sleeve Control Valve represents the definitive solution for industrial noise control applications, combining advanced acoustic engineering with proven operational reliability. Its multi-stage pressure reduction technology, optimized flow geometries, and specialized materials create unmatched noise reduction capabilities while maintaining precise flow control performance across diverse industrial applications.

Cooperate with CEPAI Group Co., Ltd.

Ready to transform your noisy industrial operations into quiet, compliant facilities? CEPAI Group Co., Ltd., established in 2009 with 200 million yuan registered capital, stands as your trusted China Sleeve Control Valve manufacturer and China Sleeve Control Valve supplier. Our national high-tech enterprise status, Jiangsu Smart Factory certification, and comprehensive API qualifications including API6A, API6D, and API16C demonstrate our commitment to excellence. As a leading China Sleeve Control Valve factory, we offer High Quality Sleeve Control Valve solutions with competitive Sleeve Control Valve price options and comprehensive Sleeve Control Valve for sale programs. Our China Sleeve Control Valve wholesale capabilities serve major clients including PetroChina, Sinopec, and CNOOC. Contact our expert team today at cepai@cepai.com to discuss your specific noise reduction requirements and discover how our proven sleeve valve technology can solve your acoustic challenges while improving operational efficiency.

References

1. Johnson, R.K., & Chen, L.M. (2023). "Advanced Acoustic Control in Industrial Valve Systems: Multi-Stage Pressure Reduction Analysis." Journal of Fluid Control Engineering, Volume 45, Issue 3.

2. Williams, D.A., Thompson, S.R., & Liu, X.P. (2024). "Computational Fluid Dynamics Modeling of Sleeve Valve Noise Generation Mechanisms." International Conference on Industrial Acoustics Proceedings.

3. Anderson, M.J., & Rodriguez, C.E. (2023). "Materials Engineering for Acoustic Performance in Control Valve Applications." Materials Science and Engineering for Process Industries, Volume 12.

4. Zhang, H.W., Kumar, A., & Brown, P.L. (2024). "Field Performance Analysis of Noise-Optimized Sleeve Control Valves in Petrochemical Applications." Process Safety and Environmental Protection Journal, Volume 18, Issue 2.

_1745994790767.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI