An electric control valve water treatment is a modern gadget planned to direct the stream, pressure, and volume of water inside treatment forms through robotized electrical activation. In water treatment, it absolutely alters the stream rate and weight to optimize refinement and dissemination proficiency. This article unloads the basics of electric control valves in water treatment, their fundamental capacities, and how they work to handle control, energy efficiency, and framework unwavering quality. Whether you oversee civil waterworks or mechanical treatment plants, understanding these valves opens up handling mechanization potential and supports water quality assurance.

What Is an Electric Control Valve Water Treatment?

Electric control valves water treatment in water treatment are necessary components that work by means of electric actuators to oversee the flow and pressure of water inside pipelines and treatment units. These valves consolidate a valve body, actuator, and positioner to convey exact control over liquid flow, empowering computerized alteration without manual intervention. By combining sensors and electronic control frameworks, these valves react quickly to fluctuating handle requests or security orders, guaranteeing consistent water quality and system performance. They involve a center position in present-day robotization systems that aim to optimize water treatment adequacy while keeping up security compliance and operational integrity. Their center work rotates around tuning stream control, empowering administrators to keep up steady water pressure and volume throughout filtration, chemical dosing, and dissemination stages. Integration with control frameworks gives real-time input circles and further checking capabilities, upgrading predictive support, and handling optimization.

The Problem It Solves and the Need It Fulfills

Water treatment offices confront the challenge of overseeing changing stream rates, pressure variances, and maintaining reliable water quality in the midst of complex pipeline systems. Conventional manual valve alterations are not as it were labor-intensive but need exactness, increasing the risk of spills, vitality squander, and conflicting treatment outcomes. Electric control valve water treatment addresses these torment focuses by presenting automation that carefully oversees the system factors in real-time. These valves fulfill the basic requirements for high-precision control in energetic situations where water demand and quality parameters alter quickly. Their capacity to control weight and stream decreases wear on pipelines and related hardware, while upgrading erosion resistance through optimized valve positioning. Also, joining savvy valve innovation with further checking and control makes a difference in identifying spills early and planning opportune upkeep, crucial for avoiding expensive downtime and guaranteeing nonstop compliance with exacting environmental guidelines. This innovation aligns with developing requests for energy efficiency and maintainability in the water treatment sector. The requirement for such valves develops in line with expanding robotization requirements and the thrust for brilliant water administration frameworks, making electric control valve water treatment a vital asset.

Core Features and Functionality Deep Dive

Electric control valves show a few center highlights that make them an irreplaceable part in water treatment systems:

- Actuator Integration: An electric actuator absolutely moves the valve stem, advertising quick reaction to control signals. This mechanization outflanks pneumatic choices in terms of exactness and vitality efficiency.

- Valve Positioner: Implanted valve positioners guarantee correct valve positioning by comparing the setpoint with the real valve position, empowering an input circle basic for keeping up steady stream regulation.

- Flow and Weight Control: These valves control stream volume and weight inside the pipeline framework to keep up ideal working conditions, basic for viable filtration and chemical dosing.

- Corrosion Resistance: Valve bodies are ordinarily built from materials safe to erosion caused by chemicals and water impurities, guaranteeing long service life.

- Automation Prepared: Compatibility with control frameworks permits further operation and integration into larger SCADA frameworks for preparation optimization and security compliance.

- Leak Discovery & Support: Progressed sensors can give early caution signals of potential spills, encouraging proactive support workflows and expanding resource life.

These electric control valve water treatment highlights combined to provide smoother operation, increased vitality proficiency, and diminished manual labor. Administrators pick up granular control over the whole water treatment chain, moving forward water quality and lessening operational risks.

Under the Hood: Technology Explained

At the heart of an electric control valve lies an electric actuator fueled by a servo engine. This actuator changes over electrical signals from a controller into mechanical movement, altering valve opening degrees precisely. Going with sensor degree parameters such as stream rate, weight, and valve position, nourishing information back to the control framework. A valve positioner acts as the middle person, guaranteeing the mechanical reaction matches commanded setpoints, shaping a tight input circle basic for high-precision control.

The electric control valve water treatment leverages standards of liquid flow to tweak the water stream without causing sudden spikes or drops in weight, essential for touchy filtration layers or chemical treatment stages. Materials science improves valve components with coatings and combinations that withstand erosive water properties, including erosion resistance and durability.

Moreover, integration with shrewd valve systems gives further checking usefulness. Administrators can get to valve status, control parameters, and upkeep alarms from centralized dashboards. This brings shrewdly prepared optimization within reach and improves security compliance by lessening human error.

Key Advantages of Electric Control Valves in Water Treatment

Electric control valve water treatment offers several significant advantages that highlight its value over traditional mechanical or pneumatic valves:

- Exceptional Solidness: Developed with high-quality corrosion-resistant materials, these valves withstand cruel wastewater situations, diminishing downtime and substitution costs.

- High-Precision Control Execution: Progressed actuators and positioners give tight control over stream and weight, optimizing water treatment forms and vitality consumption.

- Energy Proficiency: Electric initiation expends less energy compared to pneumatic frameworks, contributing to more economical plant operations.

- Automation and Inaccessible Observing: Empowers consistent integration into control frameworks, permitting preparation optimization, spill location, and preventive support from afar.

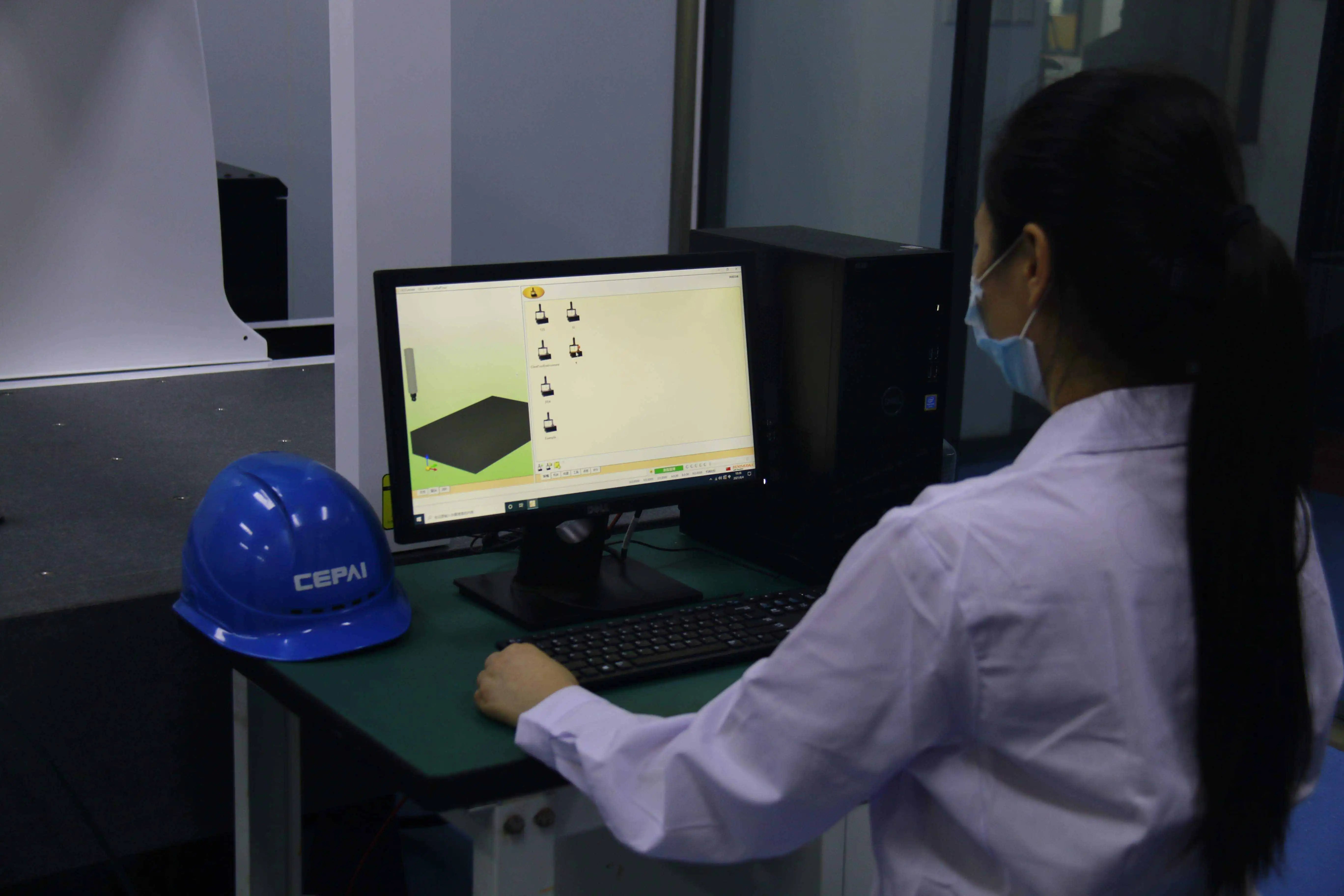

- Comprehensive Bolster Administrations: Suppliers, such as CEPAI Gather Co., LTD., offer pre-sales interview, customization, establishment, preparation, and after-sales upkeep, guaranteeing smooth arrangement and longevity.

- Compliance with Quality Guidelines: Made in line with ISO quality frameworks, these valves ensure steady execution and security, building believe in mechanical applications.

Such advantages not only improve operational reliability but also build a foundation for scalable, intelligent water management.

Potential Limitations and Considerations

Despite their many benefits, electric control valve water treatment carries some limitations and factors to evaluate before implementation:

- Initial Venture Taken a toll: These valves ordinarily include higher upfront costs due to progressed actuators and gadgets compared to manual or pneumatic valves.

- Dependence on Electrical Supply: Nonstop control accessibility is basic, making reinforcement control frameworks essential in basic operations to anticipate disruptions.

- Complexity in Support: Support requires a gifted workforce familiar with electrical components and valve mechanics, which can be an obstacle for plants with restricted specialized resources.

- Environmental Restrictions: Touchy hardware must be secured in destructive or dangerous situations, possibly requiring extra lodging or certifications.

- Compatibility Issues: Integration with bequest control frameworks might require custom communication conventions or extra interface devices.

These considerations guide buyers in balancing technological benefits against operational constraints and budgeting.

Electric Control Valve Water Treatment vs. The Competition

Comparing electric control valves with pneumatic and manual valves reveals distinct differences:

Pneumatic valves depend on compressed discuss and regularly offer quicker activation but at the fetched of higher energy consumption and less exact control, particularly in fluctuating pressure scenarios. They moreover require a broad pneumatic framework and are more vulnerable to leaks.

Electric control valve water treatment requires coordinated human intervention, restricting responsiveness and adaptability in huge or robotized water treatment plants. They present dangers of conflicting operations and slower responses to prepare changes.

Electric control valves surpass competitors by combining exact stream control, shrewd integration capabilities, and energy efficiency. Their progressive criticism components empower persistent preparation optimization concealed in options. Whereas their forthright fetched is higher, the decrease in support, vitality utilization, and human labor conveys prevalent long-term value and prepares stability.

Target Audience and Ideal Use Cases

The ideal users of electric control valves in water treatment span multiple sectors:

- Municipal Water Specialists: Where reliable water quality and supply control are fundamental in the midst of variable demand.

- Industrial Water Treatment Plants: Especially those requiring tight chemical dosing control and weight administration to ensure forms and equipment.

- Wastewater Treatment Offices: For overseeing the stream through filtration and sanitization stages with exactness to comply with environmental regulations.

- Agricultural Water System Frameworks: Where mechanization moves forward, proficiency in water conveyance and framework integration decreases manual workload.

Settings requesting inaccessible observing, spill discovery, and tall framework unwavering quality infer the most esteem from electric control valve water treatment integration. Their adaptability underpins both retrofit and unused installations.

Conclusion & Future Outlook

Electric control valve water treatment has changed water treatment by conveying exact stream direction, energy efficiency, and automation compatibility. Their progressive innovation empowers consistent integration into savvy water administration frameworks, upgrading operational security and diminishing support burdens. As water treatment requests develop near stricter environmental measures, these valves show a strong, future-ready arrangement. Progressions in actuator innovation and IoT integration are likely to amplify their capabilities, making them crucial resources for accomplishing feasible, optimized water treatment globally.

FAQ

Q1: How does an electric control valve improve water treatment efficiency?

A: Electric control valves enable precise flow and pressure adjustments via automated actuators and feedback loops. This results in optimized chemical dosing, reduced energy waste, and consistent water quality, boosting overall process efficiency.

Q2: What maintenance is required for electric control valves in water treatment plants?

A: Maintenance includes regular inspection of actuators, positioners, and sensors, lubrication of moving parts, electrical component testing, and monitoring for leaks. Scheduled servicing helps maintain accuracy and prolong valve lifespan.

Q3: Are electric control valves compatible with existing water treatment systems?

A: Yes, these valves can be integrated with most modern and legacy control systems via standard communication protocols or interface devices. Expert consultation ensures seamless system integration tailored to specific facilities.

Q4: What materials are used to ensure corrosion resistance in these valves?

A: Valve bodies often use stainless steel, coated alloys, or special polymers designed to resist chemical corrosion and abrasion common in water treatment environments, ensuring durability and safety.

Q5: How does remote monitoring enhance electric control valve performance?

A: Remote monitoring allows real-time access to valve status, diagnostics, and alerts. This supports proactive maintenance, quick fault response, and continuous process adjustments without needing on-site presence.

Q6: What industries benefit most from electric control valves in water treatment?

A: Municipal water utilities, industrial process plants, wastewater treatment facilities, and agricultural irrigation systems commonly benefit due to their requirements for precise flow regulation, automation, and reliability.

Where to Buy an Electric Control Valve Water Treatment?

When seeking reliable and high-performance electric control valves for water treatment, CEPAI Group Co., LTD. stands out with exceptional durability, advanced R&D innovations, and comprehensive service support. We provide customized solutions, technical consultation, installation, and after-sales maintenance to ensure optimal valve performance in your systems. Trust our ISO-certified manufacturing process and industry recognition as guarantees of quality. For inquiries and expert guidance on the best electric control valve water treatment options, contact us at cepai@cepai.com. Explore more details about our products and services on our blog at valveblog.jscepai.com.

References

1. "Water Treatment Process Control": An in-depth technical manual on automation technologies applied in water treatment facilities.

2. "Valve Technology and Fluid Dynamics": A guide to the physical principles governing valve function in industrial applications.

3. "Advances in Actuator Design for Industrial Valves": A journal providing new developments in electric actuators and positioners.

4. "Corrosion Resistance in Water Treatment Equipment": A study of materials and coatings enhancing valve longevity in harsh environments.

5. "Industrial Automation in Wastewater Treatment": An overview of control systems and smart valves used for process optimization.

6. "Energy Efficiency in Water Infrastructure": Research analyzing the impact of electric versus pneumatic valves on operational costs.

_1745994790767.webp)