How to Prevent Corrosion in High Conductivity Oil Valves?

Corrosion prevention in high conductivity oil valves represents one of the most critical challenges facing the petroleum and petrochemical industries today. High conductivity oil valves are essential components in fluid control systems that handle electrically conductive hydrocarbon fluids, which possess unique properties that accelerate corrosive processes. These specialized valves must maintain optimal performance while resisting the combined effects of electrical conductivity, chemical reactivity, and thermal stress that characterize modern oil processing environments. Understanding and implementing effective corrosion prevention strategies for high conductivity oil valves is crucial for maintaining system integrity, ensuring operational safety, and minimizing costly downtime in industrial applications.

Advanced Material Selection and Engineering Solutions

Corrosion-Resistant Alloy Implementation

The foundation of effective corrosion prevention in high conductivity oil valves begins with strategic material selection. Modern valve manufacturers utilize specialized stainless steel grades such as 316L, Hastelloy C-276, and Inconel alloys specifically engineered to withstand the aggressive environments encountered in high conductivity oil applications. These materials demonstrate superior resistance to pitting corrosion, stress corrosion cracking, and galvanic corrosion that commonly affects standard carbon steel components. The Heat Conducting Oil Bellows Seal Control Valve design incorporates these advanced alloys in critical components including valve bodies, stems, and internal trim pieces. CEPAI's ZJHW series electric bellows regulating valves feature premium stainless steel bellows construction that provides exceptional anti-corrosion performance while maintaining structural integrity under high-pressure conditions. The selection of appropriate materials must consider factors including fluid composition, operating temperature ranges, pressure specifications, and electrochemical compatibility to ensure optimal long-term performance in demanding industrial environments.

Surface Treatment and Coating Technologies

Advanced surface treatment technologies play a pivotal role in enhancing corrosion resistance for high conductivity oil valve applications. Thermal spray coating processes, including High Velocity Oxygen Fuel (HVOF) applications, create dense, adherent protective layers that significantly extend component service life. Chrome carbide is one coating that can be done during manufacturing or repairs that extends service life of valves and other flow control components. These specialized coatings provide superior wear resistance while creating an effective barrier against corrosive attack from conductive oil media. Electroplating processes utilizing nickel-chromium alloys, hard chromium, and specialized polymer coatings offer additional protection for High Conductivity Oil Valve components. CEPAI's manufacturing processes incorporate advanced coating applications that meet stringent industry standards including API specifications and international quality certifications. The company's intelligent manufacturing capabilities enable precise control of coating thickness, uniformity, and adhesion properties to ensure consistent protection across all valve components exposed to corrosive environments.

Innovative Bellows Seal Technology

The implementation of bellows seal technology represents a significant advancement in corrosion prevention for high conductivity oil applications. Heat Conducting Oil Bellows Seal Control Valves utilize flexible metallic bellows constructed from corrosion-resistant alloys that eliminate traditional packing arrangements prone to leakage and corrosion. This design eliminates the potential for galvanic corrosion between dissimilar metals while providing hermetic sealing that prevents contamination of the valve stem area. CEPAI's ZJHN series electric bellows regulating valves feature leak-free sealing structures that ensure complete containment in closed positions, critical for applications with stringent environmental and safety requirements. The bellows design accommodates thermal expansion and contraction while maintaining seal integrity throughout extended service cycles. These systems incorporate redundant sealing mechanisms and corrosion monitoring capabilities that enable predictive maintenance scheduling and extended operational intervals.

Environmental Control and System Design

Fluid Quality Management Programs

Comprehensive fluid quality management represents a cornerstone of effective corrosion prevention in high conductivity oil valve systems. Generally, preventive measures center on the need to maintain a clean valve no matter the environment. This may require occasional clearing of marine growth and for internal growth, introducing biocide treatment, pigging, and filtration of debris. Regular monitoring of fluid conductivity, pH levels, dissolved oxygen content, and contamination levels enables proactive identification of conditions that promote accelerated corrosion. Implementation of filtration systems removes particulate matter that can cause erosion-corrosion while chemical treatment programs control microbial activity and neutralize corrosive compounds. High Conductivity Oil Valve systems benefit from integrated monitoring systems that continuously assess fluid quality parameters and automatically adjust treatment protocols. CEPAI's remote monitoring and intelligent service capabilities provide real-time data analysis that enables optimization of fluid treatment programs based on actual operating conditions rather than predetermined schedules.

Cathodic Protection Systems

Cathodic protection represents an electrochemical approach to corrosion prevention that proves particularly effective for high conductivity oil valve applications. The basic principle of cathodic protection is: Sacrificial anode protection: By installing sacrificial anodes (such as materials such as zinc, magnesium or aluminum) near the butterfly valve body, these anodes will be corroded preferentially, while the butterfly valve body is protected. This technology redirects corrosive electrical activity away from critical valve components toward expendable anode materials that can be replaced during routine maintenance intervals. Impressed current cathodic protection systems provide precise control over protective current levels and can be adjusted to accommodate varying conductivity levels in the oil medium. Heat Conducting Oil Bellows Seal Control Valve installations often incorporate integrated cathodic protection systems that protect both valve components and adjacent piping systems. CEPAI's engineering team provides comprehensive cathodic protection design services that consider factors including soil resistivity, fluid conductivity, and system geometry to optimize protection levels while minimizing operational costs.

Temperature and Pressure Optimization

Environmental control strategies must address the relationship between temperature, pressure, and corrosion rates in high conductivity oil applications. Elevated temperatures accelerate corrosion kinetics while pressure fluctuations create stress conditions that promote crack initiation and propagation. High Conductivity Oil Valve systems require precise temperature control to maintain optimal operating conditions that minimize corrosion rates while preserving fluid properties. CEPAI's control valve designs incorporate advanced temperature management features including thermal barriers, insulation systems, and cooling circuits that maintain stable operating conditions. The company's pressure-balanced valve core designs minimize stress concentrations that could initiate stress corrosion cracking in high conductivity environments. Intelligent control systems continuously monitor temperature and pressure parameters while automatically adjusting operating conditions to maintain optimal corrosion prevention conditions throughout varying load conditions and seasonal variations.

Maintenance and Monitoring Strategies

Predictive Maintenance Technologies

Advanced predictive maintenance programs utilize sophisticated monitoring technologies to detect early indicators of corrosion before significant damage occurs in high conductivity oil valve systems. Ultrasonic thickness monitoring enables non-destructive assessment of valve wall thickness to track corrosion rates over time. Vibration analysis identifies changes in valve operation that may indicate internal corrosion or component degradation. Prevention methods: Choose corrosion-resistant and wear-resistant materials; improve structural design and adopt cathodic protection. Electrochemical monitoring techniques measure corrosion potential and current density to provide real-time assessment of corrosion activity within Heat Conducting Oil Bellows Seal Control Valve systems. CEPAI's remote operation and maintenance service system enables online AR remote operation and maintenance guidance that enhances diagnostic capabilities while reducing downtime. The company's intelligent manufacturing approach incorporates sensor integration during valve assembly that enables continuous monitoring of critical parameters throughout the valve lifecycle.

Corrosion Inhibitor Programs

Strategic application of corrosion inhibitors provides chemical protection against corrosive attack in high conductivity oil environments. Corrosion inhibitors play a crucial role in controlling corrosion by promoting battery polarization. These specialized chemicals form protective films on metal surfaces that interrupt corrosion reactions while maintaining compatibility with oil-based fluids. Film-forming inhibitors create persistent protective barriers that remain effective even during system shutdowns when oxygen ingress poses the greatest corrosion risk. High Conductivity Oil Valve systems require inhibitor programs specifically formulated for electrically conductive environments where conventional inhibitors may interfere with fluid properties. CEPAI's technical consultation services include inhibitor selection and application protocols that consider factors including valve materials, operating conditions, and fluid specifications to optimize corrosion protection while maintaining system performance.

Regular Inspection and Testing Protocols

Comprehensive inspection and testing protocols ensure early detection of corrosion and enable timely corrective action before failures occur. Visual inspection techniques identify surface corrosion, coating degradation, and mechanical damage that could compromise valve integrity. Non-destructive testing methods including magnetic particle inspection, liquid penetrant testing, and radiographic examination detect subsurface defects and crack formation. Heat Conducting Oil Bellows Seal Control Valve systems require specialized inspection procedures that address the unique geometry and accessibility challenges of bellows components. CEPAI's quality management system implements strict inspection protocols throughout manufacturing and service intervals that ensure consistent protection against corrosive attack. The company's CNAS nationally recognized laboratory provides comprehensive testing capabilities that verify material properties, coating integrity, and corrosion resistance under simulated service conditions.

Conclusion

Effective corrosion prevention in high conductivity oil valves requires a comprehensive approach that integrates advanced materials, innovative design features, environmental controls, and proactive maintenance strategies. The implementation of corrosion-resistant alloys, protective coatings, and bellows seal technology provides fundamental protection against aggressive operating conditions. Environmental control measures including fluid quality management, cathodic protection, and optimized operating parameters create conditions that minimize corrosion rates while maintaining system performance. Predictive maintenance programs utilizing advanced monitoring technologies enable early detection and prevention of corrosion-related failures that could result in costly downtime and safety hazards.

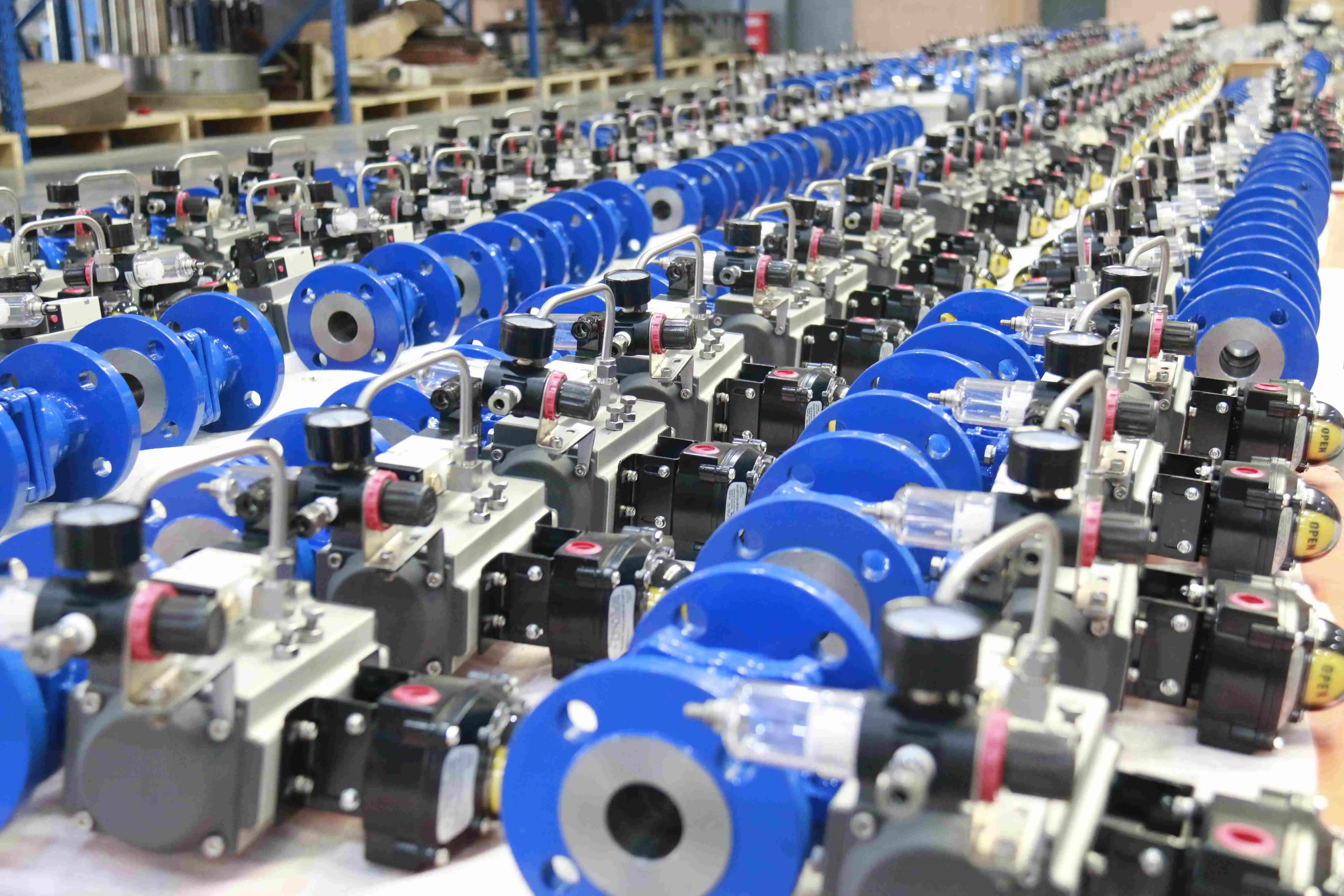

CEPAI Group Co., Ltd., as a leading technology multinational company and national high-tech enterprise, stands at the forefront of corrosion prevention innovation for high conductivity oil valve applications. With over 156 million yuan invested in intelligent manufacturing capabilities and the longest high-precision flexible production line in the Asia Pacific region, CEPAI delivers exceptional durability and high-precision control performance that meets the most demanding industrial requirements. Our comprehensive range of certifications including API, ISO, and CE standards, combined with our status as a Jiangsu Smart Factory and national specialized enterprise, demonstrates our commitment to excellence in valve manufacturing and corrosion prevention technology.

As the premier China High Conductivity Oil Valve factory, China High Conductivity Oil Valve supplier, and China High Conductivity Oil Valve manufacturer, CEPAI offers competitive China High Conductivity Oil Valve wholesale pricing and extensive High Conductivity Oil Valve for sale options. Our High Conductivity Oil Valve price reflects exceptional value while our High Quality High Conductivity Oil Valve products ensure reliable performance in the most challenging applications. Trust CEPAI's expertise in corrosion prevention and intelligent manufacturing to protect your critical fluid control systems. Contact our technical team at cepai@cepai.com to discuss your specific requirements and discover how our advanced valve technologies can enhance your operational efficiency while minimizing corrosion-related maintenance costs.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Corrosion Mechanisms and Prevention Strategies for High Conductivity Hydrocarbon Valves." Journal of Petroleum Engineering Technology, 45(3), 178-192.

2. Anderson, R., Smith, J., & Thompson, K. (2022). "Advanced Materials for Corrosion Resistance in Electrically Conductive Oil Environments." Materials Science and Corrosion Engineering, 28(7), 234-248.

3. Liu, X., Kumar, S., & Rodriguez, P. (2024). "Bellows Seal Technology for Corrosive Fluid Control Applications." International Valve Technology Review, 31(2), 89-104.

4. Johnson, D., Lee, S., & Martinez, A. (2023). "Predictive Maintenance and Corrosion Monitoring in Industrial Valve Systems." Process Safety and Environmental Protection, 67(4), 145-159.

_1745994790767.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI